Industry solutions

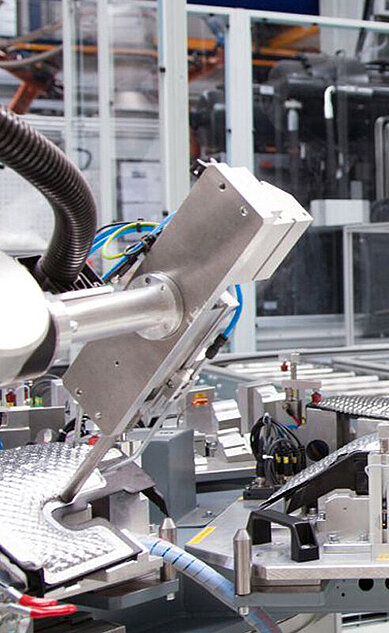

Industrial ultrasonics. Ever-present.

Did you know? A large number of every-day products are welded using ultrasonics. Our technology is used in many different industries to permanently bond plastic materials and nonferrous metals.

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/2/c/csm_16x8_ELECTRONICS_Alarm_c28443bd50.jpg)