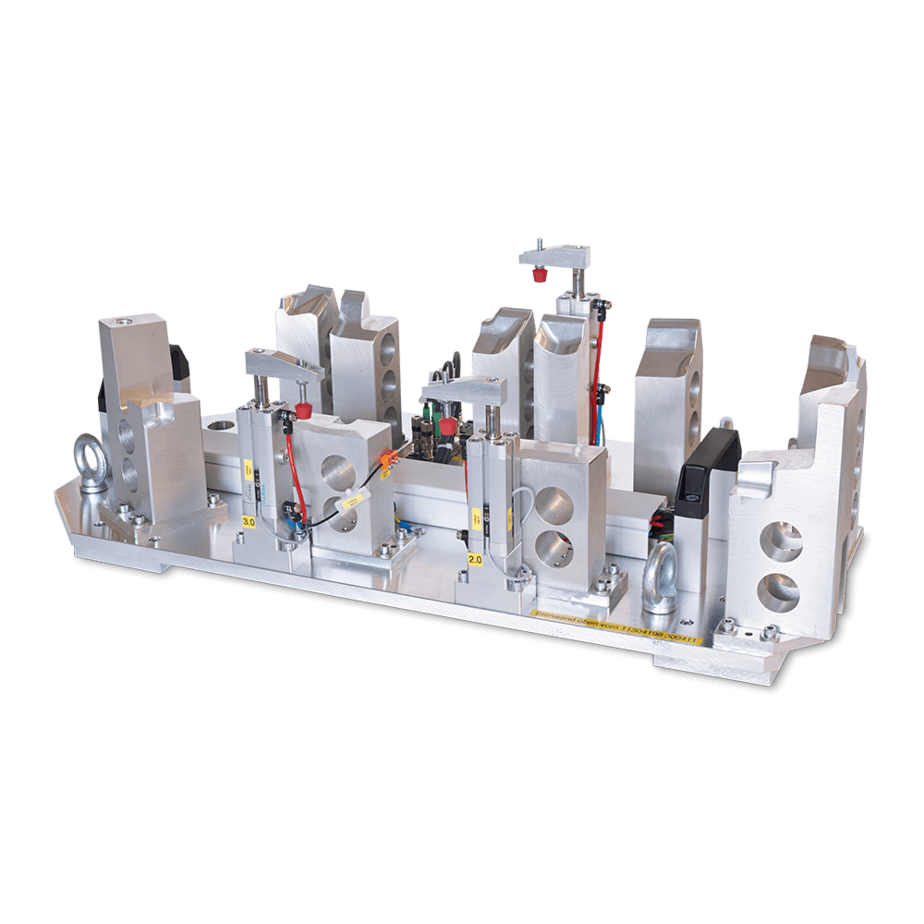

Ultrasonic Fixtures & Positioners

Equipment for the holding and fixing of the plastic application. They form the counter-bearing for the weld force which is exerted by the sonotrode.

Herrmann has long-term experience in the field of ultrasonic welding fixture design. In order to obtain good weld results, an ultrasonic welding fixture has to be perfectly adapted to the plastic component about to be welded. Starting with selection of the best suitable material, which ensures damage-free holding of the component, through to special fixing, clamping, or sensor functions, welding fixtures are customized and specifically designed to meet the respective application requirements.

Designed for Maximum Performance

Our range of modular welding fixtures are available in various materials and metals to provide optimal positioning for a successful weld. For example, fixtures made of poured urethane are highly effective for rigid plastic parts and avoid part marking that can be associated with ultrasonic welding.

The materials used for these fixtures have an effect on the energy transfer. This means they should be selected based on the particular plastic resins used in the process as well as the specific application of the ultrasonic welding procedure. In addition, the fixture needs to be manufactured to precise specifications to ensure the correct alignment between it and the sonotrode.

Adding sensors to the fixture also can help with proper part placement before beginning the welding cycle. We offer numerous designs that enable quick tool changes to make changing fixtures as fast and simple as possible.

With our extensive capabilities and comprehensive know-how, Herrmann Ultrasonics is the leader when it comes to developing and manufacturing ultrasonic welding solutions for a wide range of applications. We take pride in our ability not only to join materials together, but also to create strong bonds between ourselves and the customers we serve. We deliver equipment, engineering and solutions that take ultrasonic welding further than anyone else, making us the best in the industry. To learn more about everything we have to offer and how it can help your operations, reach out and speak with one of our representatives today.