Successful ultrasonic solutions

The concept of automation covers different fields of application for ultrasonic technology:

- Weld systems integrated in an automatic system

- individual components used in special-type welding machines

- flexible use in robot cells

All of these areas have one thing in common: their high requirements for reliability of ultrasonic technology in continuous daily operation.

Increasing process quality and speed through automated ultrasonic welding

A stronger, more stable and environmentally friendly joining process for ABS sheets: That was the goal of automating the process of assembling engine bonnets for lawn mowers using a collaborative robot. With the integration of efficient and reliable ultrasonics welding technology from Herrmann Ultraschall onto a collaborative welding head from ZLIN ROBOTICS s.r.o., this process could be optimized by permanently increasing the process speed and quality in the long term.

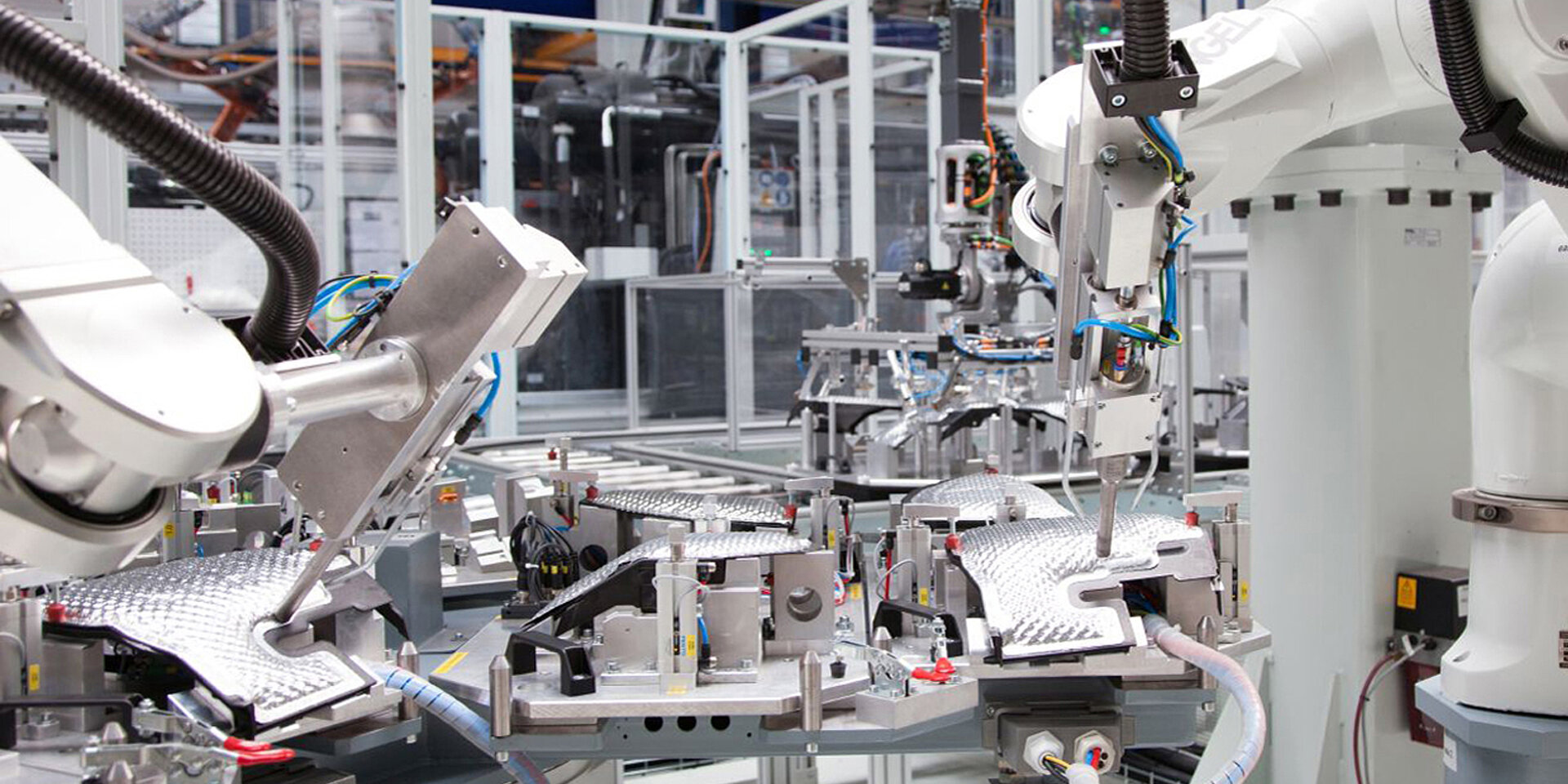

Industrial Automation

Ultrasonic welding processes often need to be integrated into complex automation lines as individual production steps. Self-contained systems with separate weld process controllers are used for this purpose.

This way even the most complex types of weld applications can be integrated and implemented in automation processes in a reproducible manner. Systems by Herrmann ensure easy start-up.

- Easy system integration

- High precision

- Weld process control

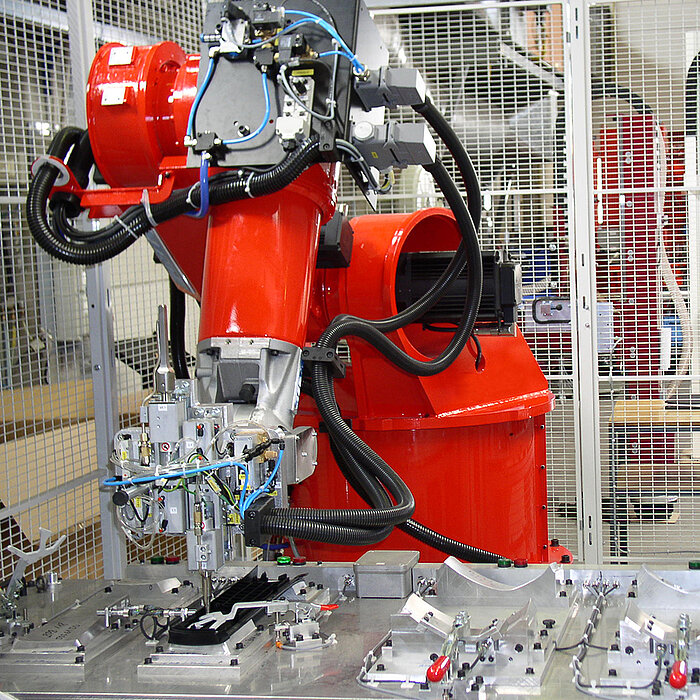

Multihead components

For builders of customized machines, specially designed ultrasonic generators and converters

are available for selection. In this context we specifically adapt to and try to meet our

customers’ requirements to ensure maximum utilization of the work space.

The actuators from the COMPACTLINE product line, complete the product range for

multi-head weld applications.

- Robust components

- Modular system

- Adapt to meet customer requirements

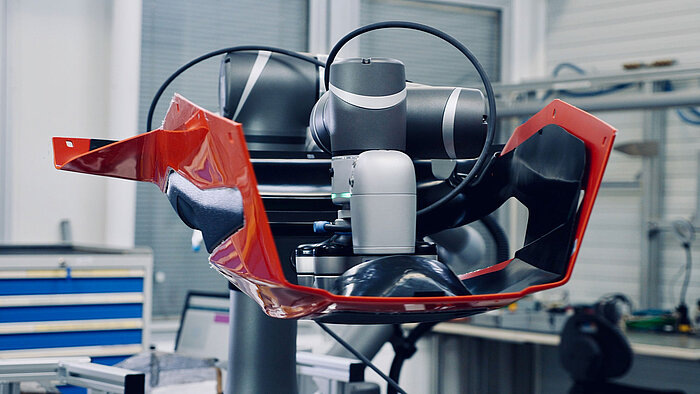

Flexible robot cells

To meet the requirements for flexibility in production due to great variant diversity and small batch sizes, robot systems are increasingly used. Despite continuous stresses acting on the ultrasonic components, excellent reproducibility from weld spot to weld spot is required.

Thanks to the PreLoaded concept, the non-production times as part of the overall cycle times are considerably reduced.

- Permanent reliability

- Cycle-time optimization by PreLoaded

- High degree of production flexibility

Download Expert Resources

Learn more about the benefits of our ultrasonic welding technology for your automated manufacturing process. Our downloads contain knowledge from more than 60 years of ultrasonics, providing valuable insights into advanced assembly techniques. By sharing our technical expertise, we foster a close partnership on equal terms, ensuring we can execute projects as quickly and successfully as possible.

Download our exclusive resources to unlock decades of innovation and stay ahead in the automated Industry 4.0 era.

Partner with Us

Contact our team to discover how our premium solutions can elevate the quality and effectiveness of your large-scale manufacturing. We look forward to hearing from you!