Ultrasonic Film Welding

Film welding is significant for the packaging industry. Thin films can be welded to each other, or to other materials. This is how coffee capsules, drink packaging and much more are made. The reason ultrasonic welding of films works so well is that heat is generated within the material and not applied from outside. This means that the exterior of the film maintains its quality features and barrier properties.

This is how it works

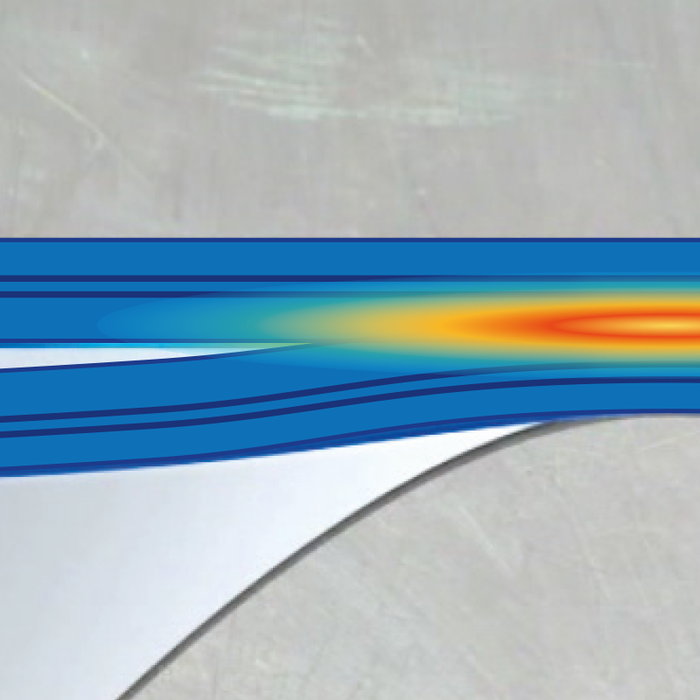

The high voltage produced by the generator is transformed into mechanical vibration (ultrasonic) in the converter. The weld tool (sonotrode) transfers this to the films to be welded. Friction heat is generated internally in the films extremely quickly. The pressure from the sonotrode on the film against the anvil creates the weld joint. Once the vibration has stopped, the joint solidifies in milliseconds, keeping the tooling cool.

The ultrasonic waves cause the molecules of the layers positioned on top of one another to vibrate. The friction leads to local heat development at the contact points of both layers. There, the materials are joined and a weld joint is formed. Once the joint is cooled down, the connection is as solid as the starting materials.

Utilized in many industries

Film welding serves a critical purpose across numerous sectors. Although the most obvious application for plastic film welding is to create packaging for consumer products, the process is also used for a wide range of applications where other methods of joining materials may not be suitable. For example, the medical device industry uses it to join or embed especially thin membranes that could not be easily secured otherwise. Ultrasonic welding of polyester fabrics is a common practice used in the production of diapers and other hygienic products.

Herrmann Ultrasonics delivers solutions used in a broad range of industries, including:

- Food Packaging

- Medical

- Consumer Goods

- Fabrics

- And much more

Providing the ideal solutions

Herrmann Ultrasonics offers the solutions required to have the most effective and efficient welding of suitable plastics no matter what the application. For example, Herrmann Welding Modules are the perfect solution when it comes to welding thin films together. These are especially useful for materials that cannot withstand extreme heat. This quality makes our modules the ideal answer for PET welding, as welding arcs and torches destroy PET films almost immediately and render them unusable.

Welding plastic sheets can be a good use of this technology, but it depends on the thickness of the materials being joined. Once the materials pass a specific thickness, it is recommended that other techniques for joining them be used. For instance, welding polyethylene sheets must be performed with a clear understanding of the material’s properties and how various welding methods may affect its properties and the integrity of the finished product. Without the right knowledge, there is the possibility that you may select the wrong welding method and risk damaging your materials or creating products that will not be able to withstand the prescribed usage or conditions. Our expertise when it comes to the ultrasonic welding of plastics means we can help you determine whether or not ultrasonics will be the ideal solution for your project’s specific needs.

Ultrasonic sealing

Visually appealing, long shelf life and 100% tight – this is what the ultrasonic sealing of packaging can achieve.