Ultrasonic sealing

Ultrasonic sealing is perfect for packaging solutions in the food industry. Visually appealing, long shelf life and 100% tight – these are the criteria for manufacturers and consumers. This is why this type of sealing is perfectly suited for:

- Thermoplastic films for bags, e.g. salad from the chiller or ready-meals in bags

- Cardboard packaging with thermoplastic coating, e.g. drinks cartons

- Valves on films/filter materials, e.g. degassing vent when packaging coffee beans

- Screw caps on coated cardboard packaging/films, e.g.: seals on milk

- Secure Top Seals for Food Packaging: strong, reliable seals ideal for food applications like ready-made meals, drinks, and even wet pet food in stand-up pouches and sachets

- Carton Packaging solutions: secure, hermetic top seals for drink cartons and sealing of screw-on spouts

- Functional Packaging Features: seamlessly integrate various functionalities into your products, such as filter or degassing vents for coffee packaging

- Recloseable Packaging Options: fast and reliable seals for applications like bonding of caps in standcaps and spouts in bag-in-box systems

Herrmann Ultrasonics is recognized as the leader in this technology, which is why our customers count on us to deliver everything from ultrasonic bag sealing equipment to ultrasonic spout sealing technology.

Unlike heat sealing, which melt plastic films slightly and press them together, ultrasonic sealing uses high-frequency vibrations to affect the materials on a molecular level. This process consumes less energy, produces less packaging waste and requires less maintenance than sealing with heat.

It also can be used to seal a wider variety of materials because of its lower operating temperature. These are just a few of the many reasons why our ultrasonic sealing is preferred when it comes to using sealing technologies.

This is how ultrasonic sealing works

Ultrasonic sealing utilizes the principles of ultrasonic energy to join two materials together. Weld tools (anvil or sonotrodes) focus the ultrasonic energy on the point at which the welding should take place, and friction heat is generated. The sealing time is between 100 and 200 milliseconds. Unlike heat sealing, the heat required in an ultrasonic sealer is only generated within the materials being welded. The tools remain cold and support the dissipation of heat. The hot-tack resistance (strength of the seam directly after welding without cooling) is also significantly higher than with other welding methods. The speed, reliability and overall quality of the finished seams make ultrasonic sealing equipment vital across numerous industries.

More about the ultrasonic sealing of films

Ultrasonic Film Welding

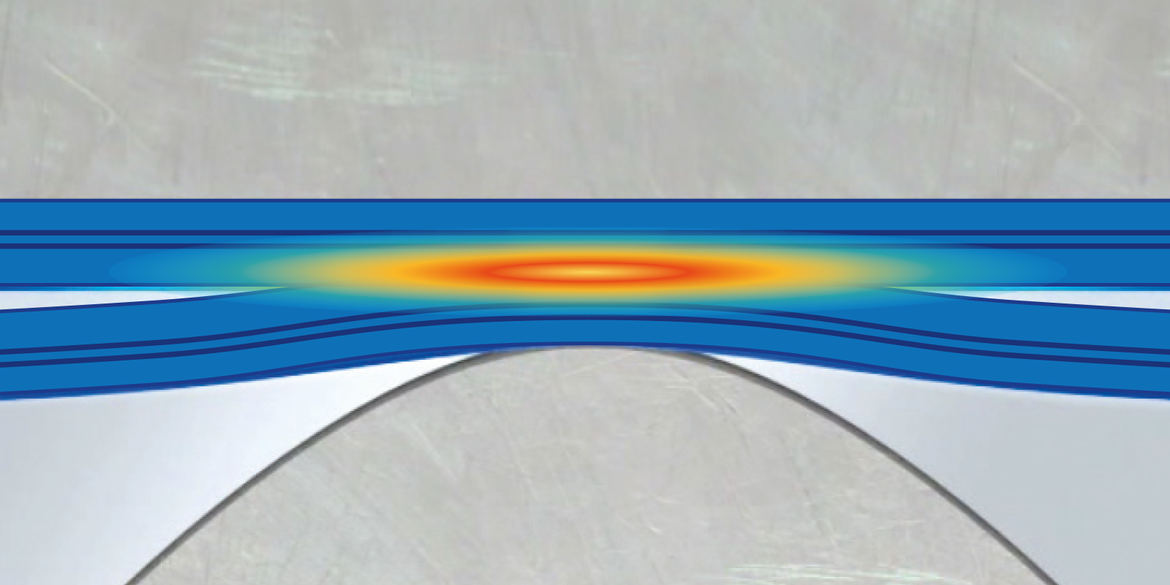

For precise welding in ultrasonic sealing machines to take place, the energy from the ultrasonic waves must be focused (energy focusing). This is either achieved via the tool geometry or the joint design on the material. In the case of joint design, the area at which the material is to be joined has special shapes such as points or edges. In the case of tool geometry, sonotrodes or the anvil are specially shaped to focus the energy.

There are several common types of joint designs that are used with ultrasonic sealing machines, with the key differences between them being the shapes stamped into the surfaces being joined. Which joint design works best depends on the materials, the weld requirements, the equipment being used and the specific appearance required by the customer.

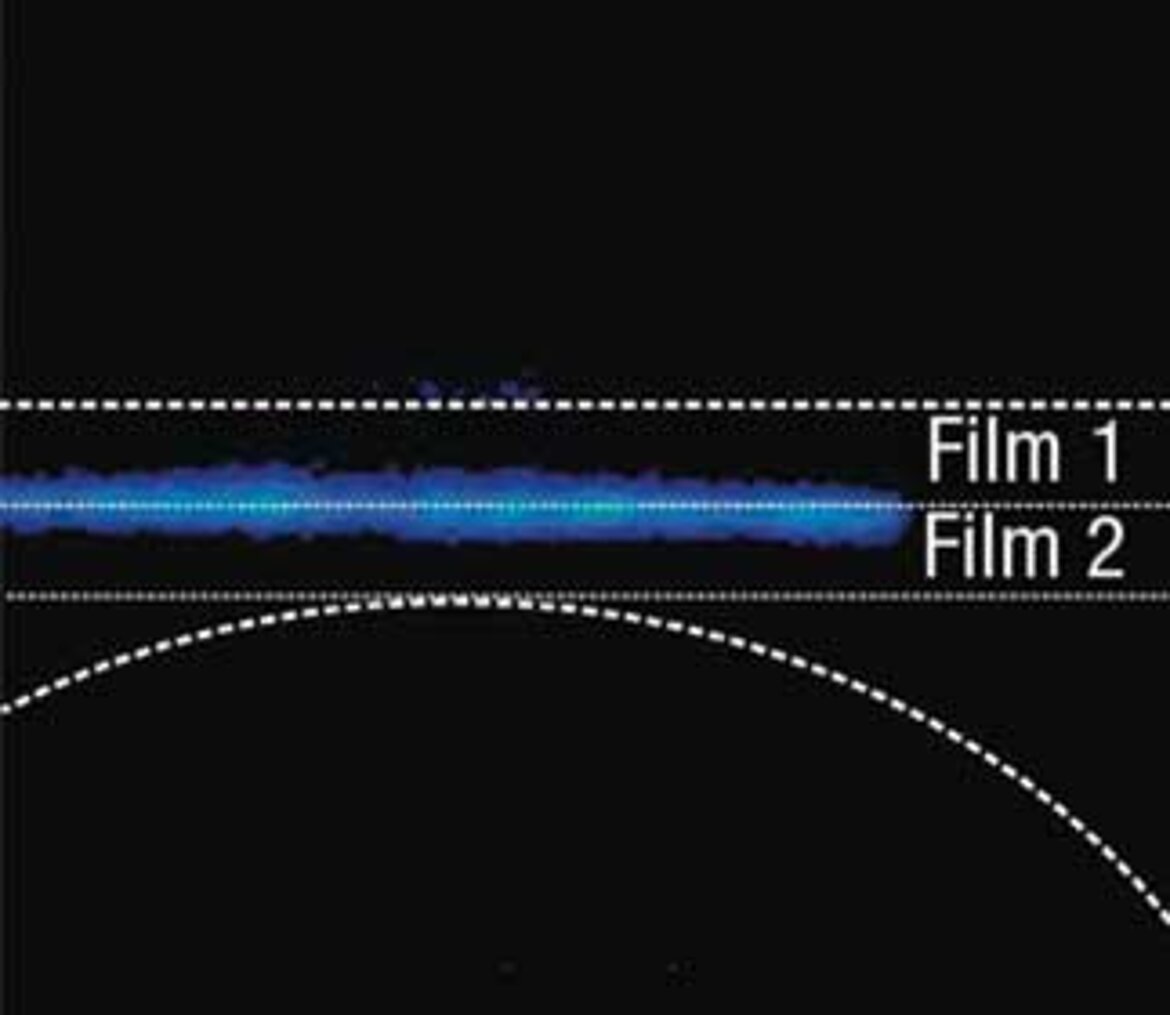

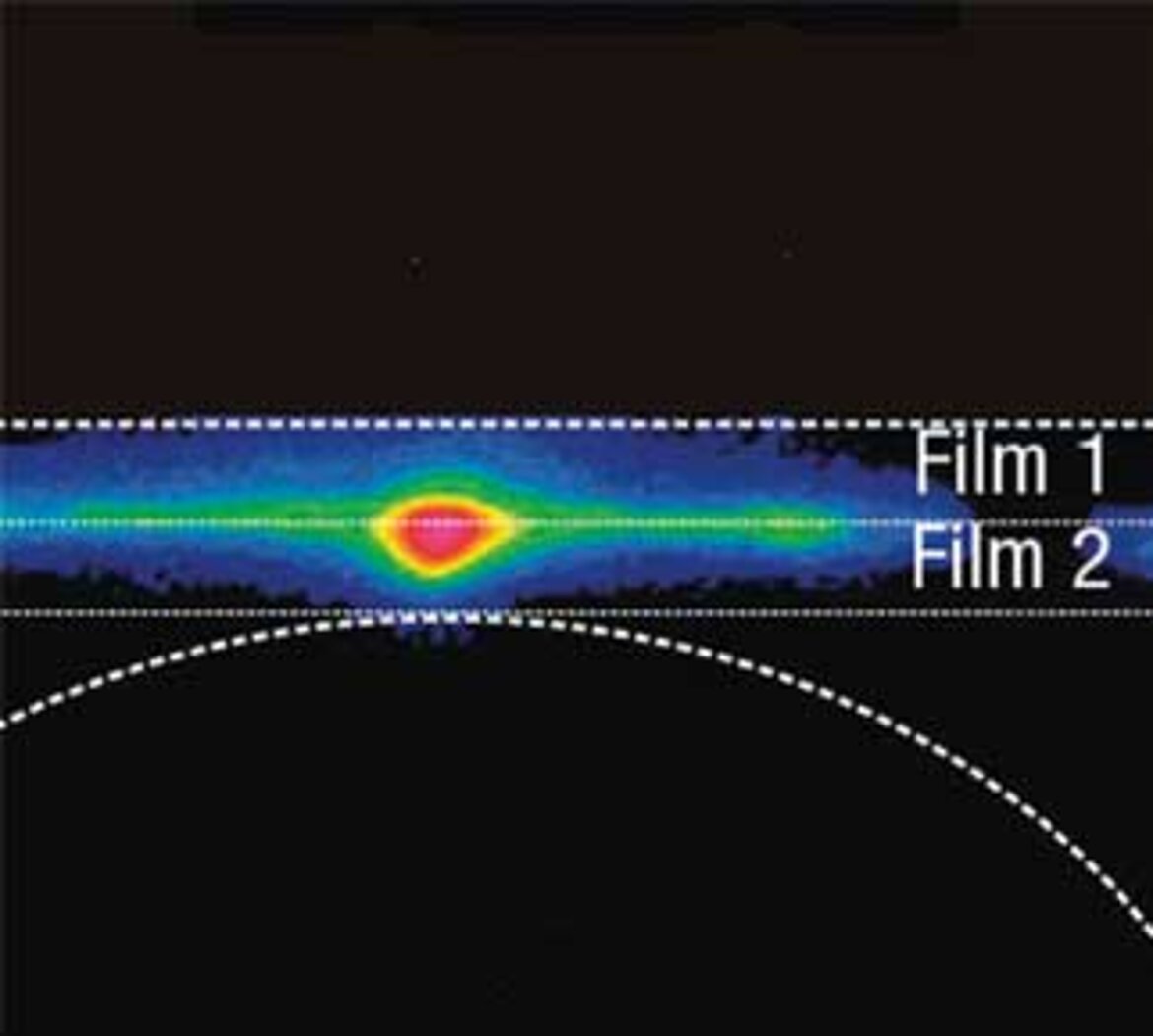

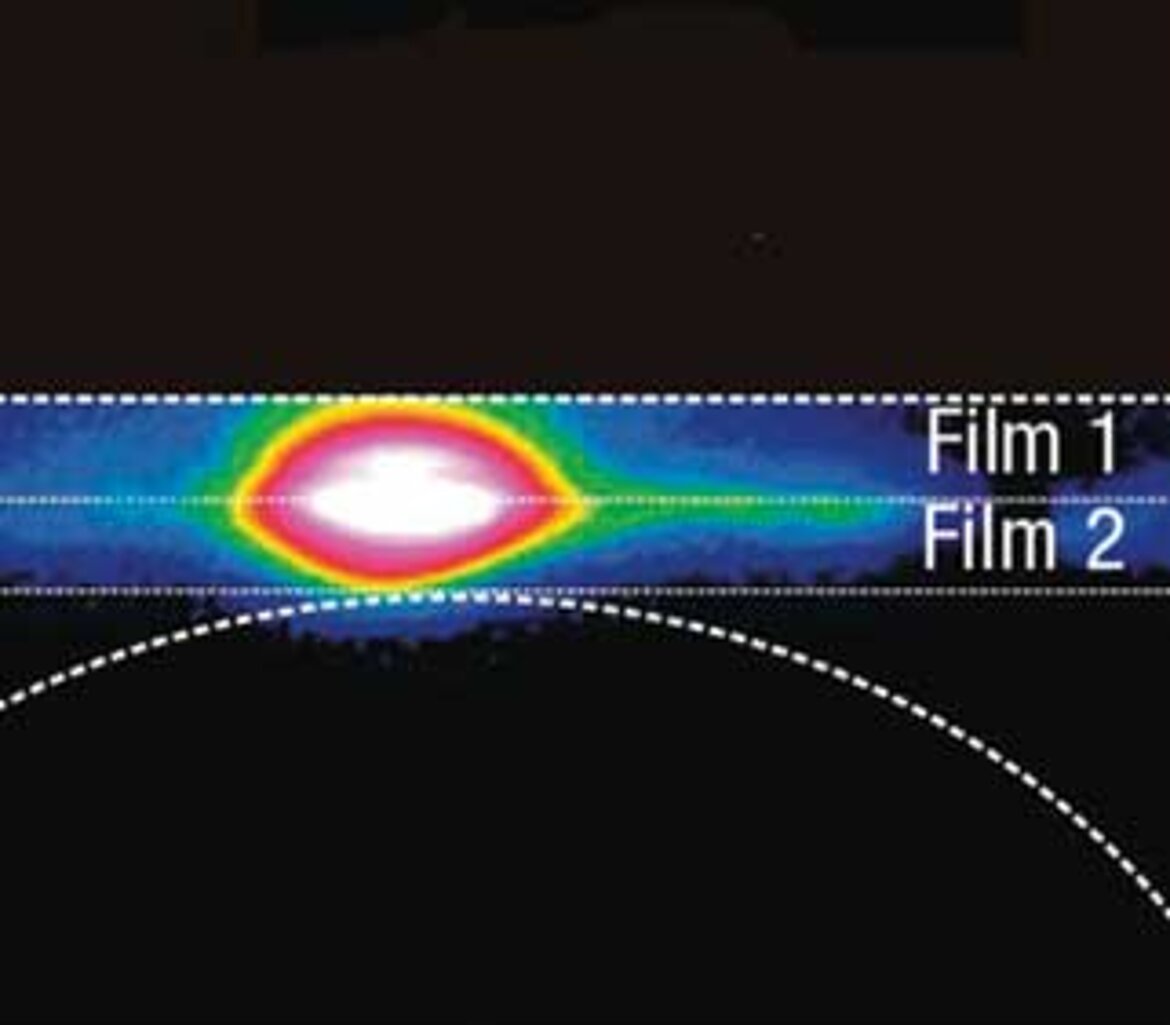

Examples of seal upgrades

Why Work With Herrmann Ultrasonics?

Since 1976, we have been the leader when it comes to innovative and effective ultrasonic sealing and welding technologies. Examples of our equipment and systems can be found across a broad spectrum of companies around the world. These include consumer goods, food packaging, non-woven textiles and automotive manufacturing.

With facilities in strategic locations across the globe, we are uniquely positioned to serve customers virtually anywhere. They trust us to provide them with the expertise and experience needed to solve their needs with the ultrasonic sealing machines and other solutions that provide the highest levels of efficacy and efficiency for their operations.

No matter how challenging the application may be, we leverage our history of innovation and industry-leading equipment to provide them with the capabilities they need to get the job done the right way.

To learn more about our advanced ultrasonic sealing technology and how it leads to the best sealing equipment on the market, reach out and talk to one of our experts today.