Company

BONDING – MORE THAN MATERIALS

What makes Herrmann so special? What motivates us? We don't just want to bond materials, but most importantly the people behind them. From customers, partners and suppliers to employees and their families, all the way to our community, we want to bring together all those with whom we come into contact.

BONDING - MORE THAN MATERIALS is our central idea that unites us and drives us to perform at our best every day. It is the reason why our customers trust us. It is our WHY.

Welcome to Herrmann Ultrasonics

... the machine and system supplier for industrial ultrasonic technology. Ultrasonic welding is used whenever two plastic parts have to be put together permanently: the two half-shells of an electrical toothbrush, a printer cartridge or a medical infusion collector. But also toys, writing utensils and even vacuum cleaner bags are welded using ultrasonics. Classic application options for the automotive industry are dashboard instruments, center consoles or cup holders. What else is possible with ultrasonic: Sealing of packaging for salad and cheese bags, drink cartons and coffee capsules. Laminating and embossing of nonwoven materials, embossing of surgical facial masks, production of baby diapers.

Business division Production of ultrasonic welding machines, systems, and components Year of foundation

1961 Herrmann Ultraschalltechnik GmbH & Co. KG – founded by Walter Herrmann

1990 Herrmann Ultrasonics, Inc. – founded by Thomas Herrmann

2003 Herrmann Ultrasonics (Taicang) Co. Ltd. – founded by Walter Herrmann

2015 Herrmann Ultrasonic Japan Corporation - founded by Thomas Herrmann

Number of employees

520 employees world-wide

North American Corporate form

Herrmann Ultrasonics, Inc. with:

Walter Herrmann, Chairman of the Boards

Thomas Herrmann, Global CEO

Uwe Peregi, President

Portfolio

Supplier of ultrasonic welding machines, systems and components for joining of thermoplastic materials

Manufacturer of modules and components for ultrasonic sealing stations in the packaging industry

System supplier for continuous and intermittent manufacturing processes for nonwoven materials, web materials, films, or filters

Ultrasonic engineering services: Application consulting, application optimization, machine integration

Implementation of more than 1000 customized solutions per year for a broad customer base.

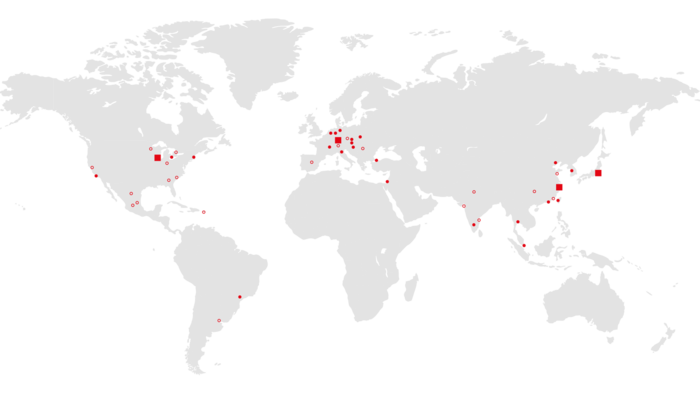

Local facilities

Headquarters in the USA, Bartlett near Chicago – President Uwe Peregi

Headquarters China, Taicang, near Shanghai – General Manager Shizhen Cheng

Headquarters Japan, Kashiwa City near Tokyo – General Manager Sohei Fukai

Tech-Center in USA, Mexico and world-wide

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/1/9/csm_16x8_Qualitymanagement_f319097b43.jpg)

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/1/0/csm_16x8_Partner_5202f062dd.jpg)