HiS SYSTEMS

Leading in process stability and precision. Whether you are using a manual work station or require integration into production lines, Herrmann has the solution for extremely strong and conductive metal connections. Fast setup and fewer suspect parts save considerable costs.

- Cost savings through higher production quality

- Long term proven ultrasonic components

- Digital Ultrasonic Generator

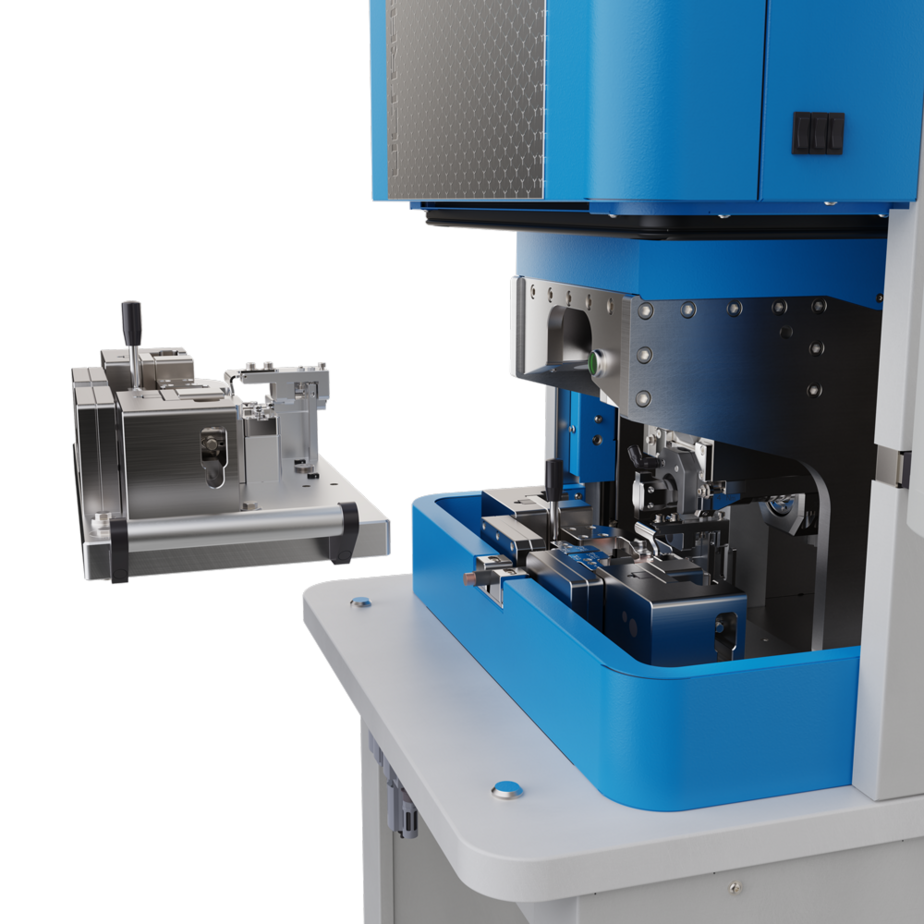

Ensuring and monitoring quality is the main focus in metal welding. Setup of the process in a stable and reproducible manner and always keeping an eye on it via the graphic visualization - these tasks are met by the HiS product line by means of the VARIO Control controller. In addition, it ensures fast tool change for both the weld tool and the equipment of the application, as well as a space-saving design for easy integration. The well thought-out design guarantees cleanliness when working, accessibility, and maximum safety for the operator.

The HiS VARIO S offers high performance and flexibility for automators. The system can be easily integrated into production lines and is impressive due to its compactness and accessibility. All features for quick tool change and production start-up have been rethought to substantially reduce change over and maintenance times. The solution achieves excellent cost savings by ensuring outstanding production reliability and quality.

The 20 kHz frequency is suitable for all battery applications with multi-layer films or thick materials in wire-to-terminal applications.

- Precise alignment

- Easy and fast tool change

- Modularity and flexibility for automation engineers

Precise alignment

-

Patented alignment module for fine adjustment of the sonotrode (plane-parallel alignment)

-

Coarse alignment possible every 90°

-

Fixed axial position guarantees the same absolute weld distance with every sonotrode change

-

Additional support of the sonotrode at the nodal point for long-term stable welds

Quick and easy tool change

- Innovative design of sonotrode and mounting bracket guarantees stability

- Accessibility from the front

- Tool change possible inline and outside

- Precise sonotrode change in just a few minutes

Modularity and flexibility for automation engineers

- Left and right-hand version

- Mechanical interfaces can be installed on several sides

- Configuration with and without anvil fixture

- Various fieldbus interfaces for communication (EtherCAT, ProfiNet PROFINET IO (RT), EtherNet/IP and others)

- Additional function and software options (sonotrode cooling, converter cooling, DataRecorder for data evaluationg)

Footprint

- Industry-leading compactness and small size

- Free feed options with automation

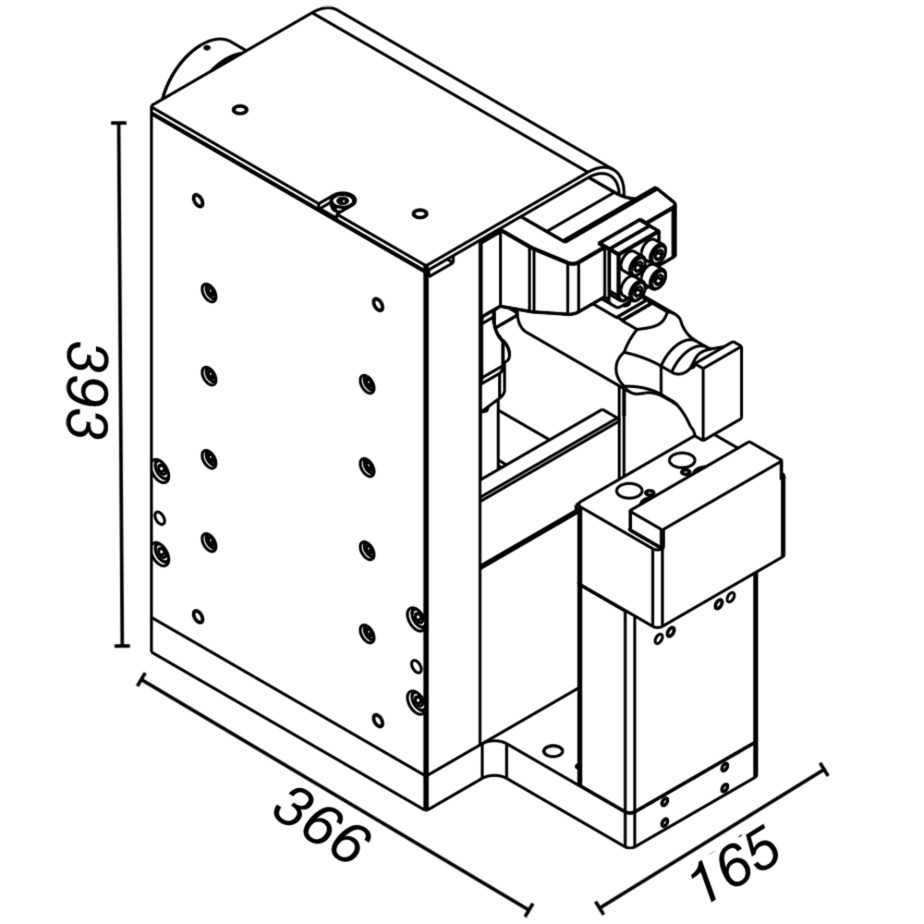

| HiS VARIO S 20 (left and right version) | 20 kHz |

|---|---|

| Generator power [W] | 2400 / 4800 / 6200 |

| Weld force max [N] at 6 bar | 3500 |

| Stroke [mm] | 15 / 30 / 60 |

| Outside dimensions (W x H x D) [mm] | 191 x 415 x 345 |

| Control Panel | 12" touch screen, color |

| Operating modes | 5 |

| Application memories | 32 |

| Number of stored welds (graphics & data) | 100 |

| Control of auxiliary functions (optional) | 4 |

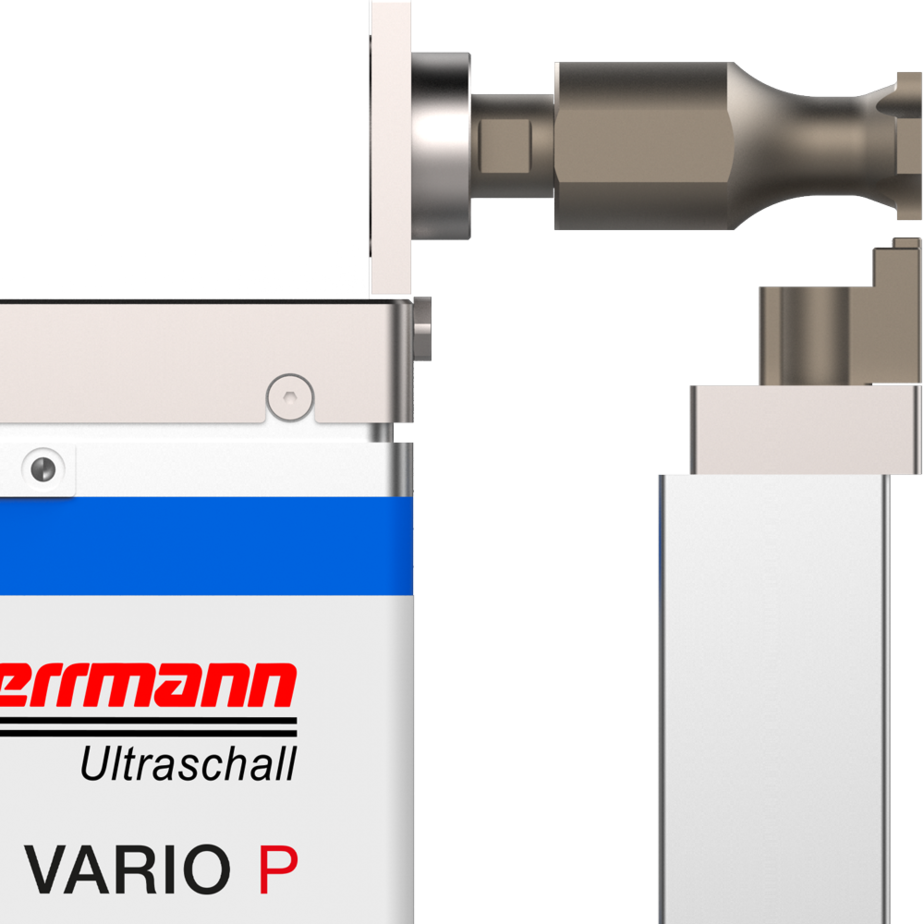

The HiS VARIO P offers the highest precision, even at small weld forces. The system can be easily integrated into production lines and is impressive due to its compactness and accessibility. All features for quick tool change and production start-up have been rethought to substantially reduce change over and maintenance times. The solution achieves excellent cost savings by ensuring outstanding production reliability and quality.

The 35 kHz frequency is ideally suited for the secure connections in battery applications with a low number of layers and wire-to-terminal applications with the smallest material thicknesses and diameters.

- Precision

- Easy and fast tool change

- Modularity and flexibility for automation engineers

Precise, low weld forces

- Newly developed rocker system (force range of 5 - 260 N)

- High degree of reproducibility of weld force in the lower force range

- Sequential drive concept

Easy and fast tool change

- Indexed tool change system

- Optimum accessibility

- Tool change possible both inline and outside

- Accurate sonotrode change in just a few minutes

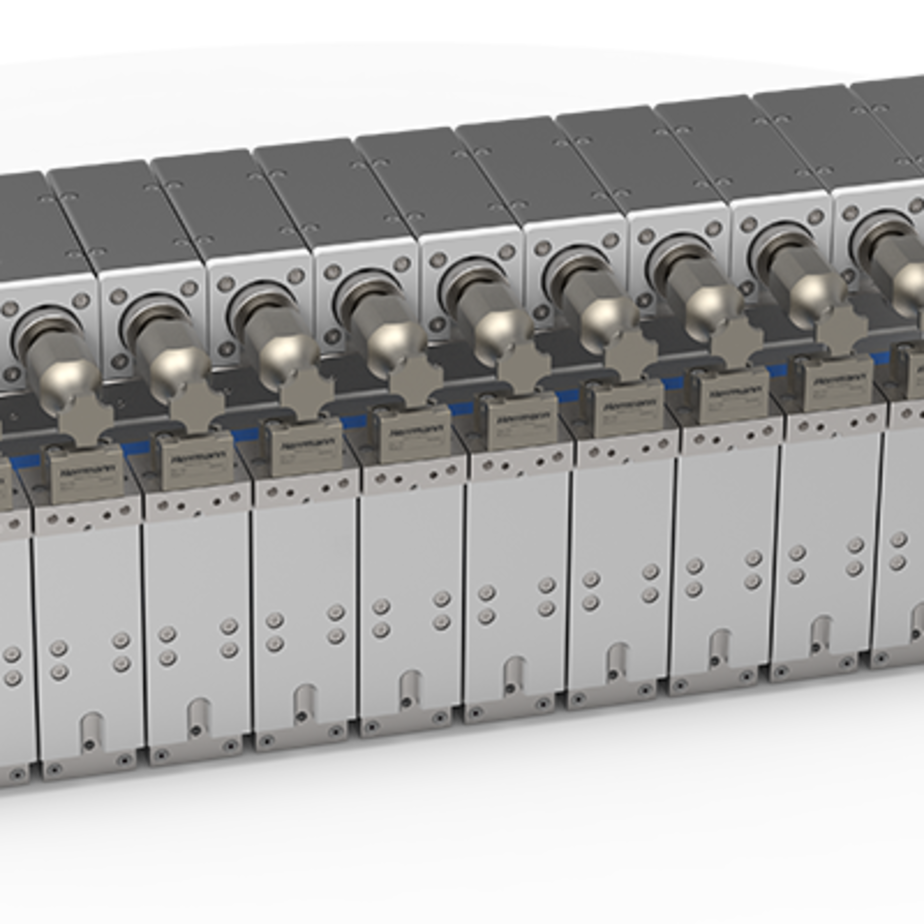

Modularity and flexibility for automation engineers

- Compact arrangement of weld modules

- Mechanical interfaces at several points

- Individual main stroke and weld force can be selected

- Various fieldbus interfaces for communication (EtherCAT, ProfiNet PROFINET IO (RT), EtherNet/IP and others)

- More function and software options (sonotrode cooling, converter cooling, DataRecorder for data analysis)

Footprint

- Industry-leading compactness and small size

- Free feed options with automation

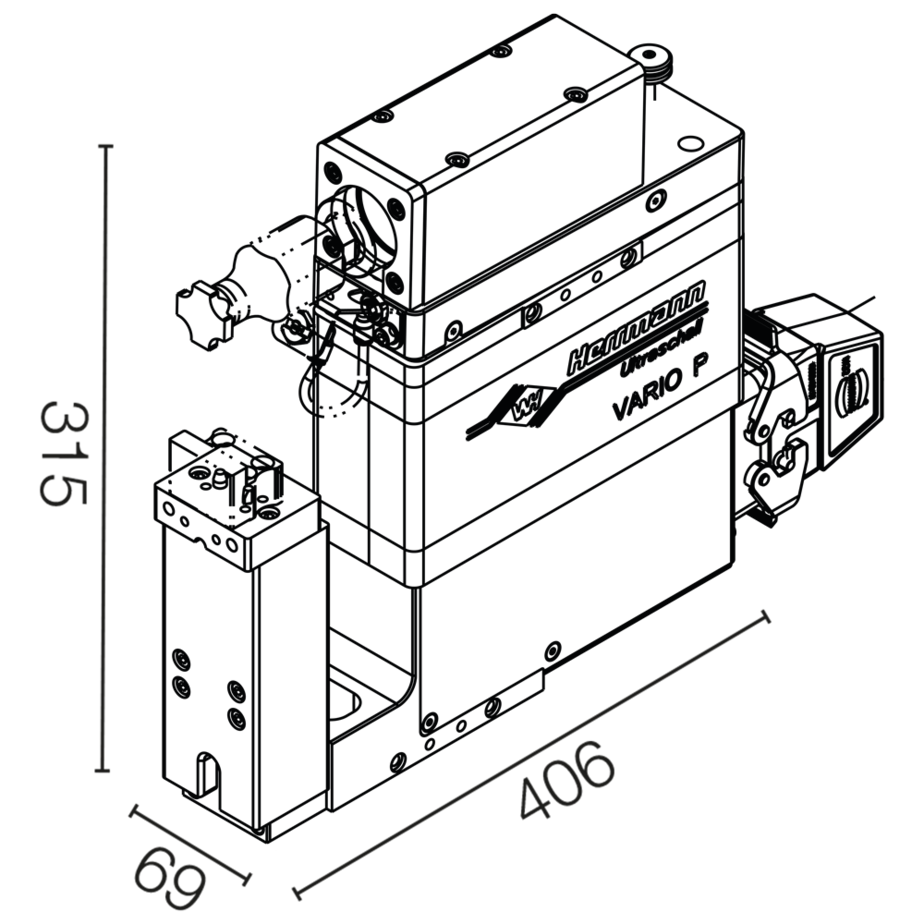

| HiS VARIO P 35 | 35 kHz |

|---|---|

| Generator power [W] | 1200 |

| Weld force max. [N] at 6 bar | 115 / 260 |

| Stroke [mm] | 10 / 30 / 50 |

| Outside dimensions (W x H x D) [mm] | 69 x 315 x 406 |

| Control panel touch screen color | 8,4" |

| Operating modes | 5 |

| Application memories | 32 |

| Number of saved welds (graphs & data) | 100 |

The HiS VARIO X is an extremely versatile system for integration into automated production lines. Its ultra-high performance allows for strong, reliable connections in demanding wire-to-terminal applications as well as battery applications with a high number of layers or large dimensions. It allows for quick changing of applications as well as safe and easy exchange of the weld tools. Well thought-out functions and interfaces make it easier to integrate the work station into the overall line. It offers the utmost precision for outstanding production reliability and quality.

- Precise alignment

- Safe and quick application change

- Safe and repeatable tool change

- Quick, safe and precise adjustment of the individual functional elements, such as the sonotrode position and interchangeable fixture

- Optimum support of the sonotrode in the tooling mount for reproducible weld results

Easy change of tools and applications

- Innovative equipment concept for a wide range of parts and applications

- Equipment indexed and changeable with plug-in type connections

- Rapidly exchangeable format sets

- Innovative design of sonotrode and tooling mount guarantees stability

- Precise sonotrode change in a few minutes

- Clamping system for changing the tooling mount

| HiS VARIO X 20 | 20 kHz |

|---|---|

| Generator power [W] | 6200 / 12000 |

| Weld force max [N] at 6 bar | 10000 |

| Stroke / Revision stroke [mm] | 60 |

| Outside dimensionse (W x H x D) [mm] | 512 x 970 x 680 |

| Control panel (weld process control) | 12“ / 9“ Touchscreen |

| Operating modes | 5 |

| Application memories 32 | |

| Number of saved welds (graphics & data) | 100 |

| Number of controllable auxiliary functions (optional) | 4 |

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/d/5/csm_MA.HIS.ULTRASAFE_W_2002_9e227ded13.png)