LSM Fin Longitudinal Seal Modules

The latest generation of our Longitudinal Seal Module (LSM) ensures reliable continuous longitudinal seals on FlowWrapping machines even with the narrowest of process windows.

Benefit from:

- Reliable sealing of sustainable packaging materials such as mono materials

- Safe process even with varying process speed

- Modular assembly for easy changeover, cleaning and retrofitting

Seal your pillow bags, chain bags and many other applications with the new LSM and become safer and more sustainable!

Popular applications for the LSM

Fuji Machinery

"With Herrmann's ultrasonic solution, we are able to seal Bio based PE films in which we had difficulties with the standard heat sealing. And with this we were able to realize a complete packaging machine."

R&D Team, Fuji Machinery

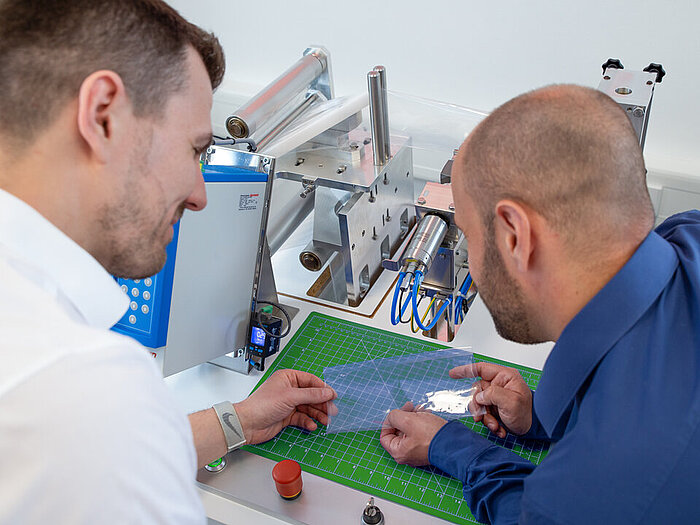

How the Longitudinal Seal Module works

The LSM creates tight seals by continuously feeding film through the stationary tools. The sealing force and amplitude can be quickly adjusted during the process. This guarantees consistent, excellent sealing results — even at varying production speeds.

Thanks to the modular design, all components are easily accessible, allowing cleaning work to be carried out quickly and conveniently. All the settings are preserved for the reassembly.

- High process stability at varying process speed

- Minimum space requirement due to compact design

- Rapid adjustment of the process parameters due to electronic settings

Safe sealing of sustainable packaging materials

Thanks to it’s guiding unit, LSM has now an even more precise control of central sealing parameters, such as the force applied during the sealing process. This ensures consistent high-quality results, which is especially beneficial for the increasing requirements of materials like Mono-materials or paper-based packaging.

Reliable seals with varying process speed

We know how important it is to adapt the speed of flow wrappers or other packaging machines to varying infeeds of the product. The longitudinal seal module gives packers full flexibility here: unlike thermal sealing processes, the speed of ultrasonic sealing can be flexibly adjusted from standstill up to 120 meters per minute. The quality of the seals always remains excellent.

Modular assembly for easy changeovers and retrofitting

Thanks to the modular design of the longitudinal seal module, functional elements can be individually assembled or retrofitted separately. This allows us to customize the LSM perfectly to your specific applications.

Partner with Us

Contact our PACKAGING Team to discover how our premium solutions can elevate the quality and effectiveness of your large-scale manufacturing. We look forward to hearing from you!