Secure and Fast Connections for Cables of all Cross-Sections

Benefit from fast production cycles of just a few seconds: With up to 12,000 W of power, you can reliably connect cables with even the largest cross-sections in the shortest possible time.

Thanks to our innovative converter architecture, you no longer need any cooling times. This ensures maximum OEE when creating strong wire-to-terminal or terminal-to-terminal connections.

Weld your cables or busbars with ultrasonics and increase your output!

Your benefits of ultrasonic welding:

- High strength

- No losses in conductivity

- Short cycle times without cooling times

- Permanent process monitoring

- Reliable and reproducible connections

Ultrasonic solutions for wire and terminal applications

Wire to terminal

In modern motor vehicles, connections of cable and contact part are indispensable, especially when it comes to ensuring the transmission of high power in the cable harnesses. Ultrasonics is used to weld copper or aluminum cables with cross sections ranging up to 150 mm² to the terminals.

Ultrasonic welding has proven to be a particularly suitable joining technology for these applications, as the connection produced meets even the highest demands in terms of strength and durability.

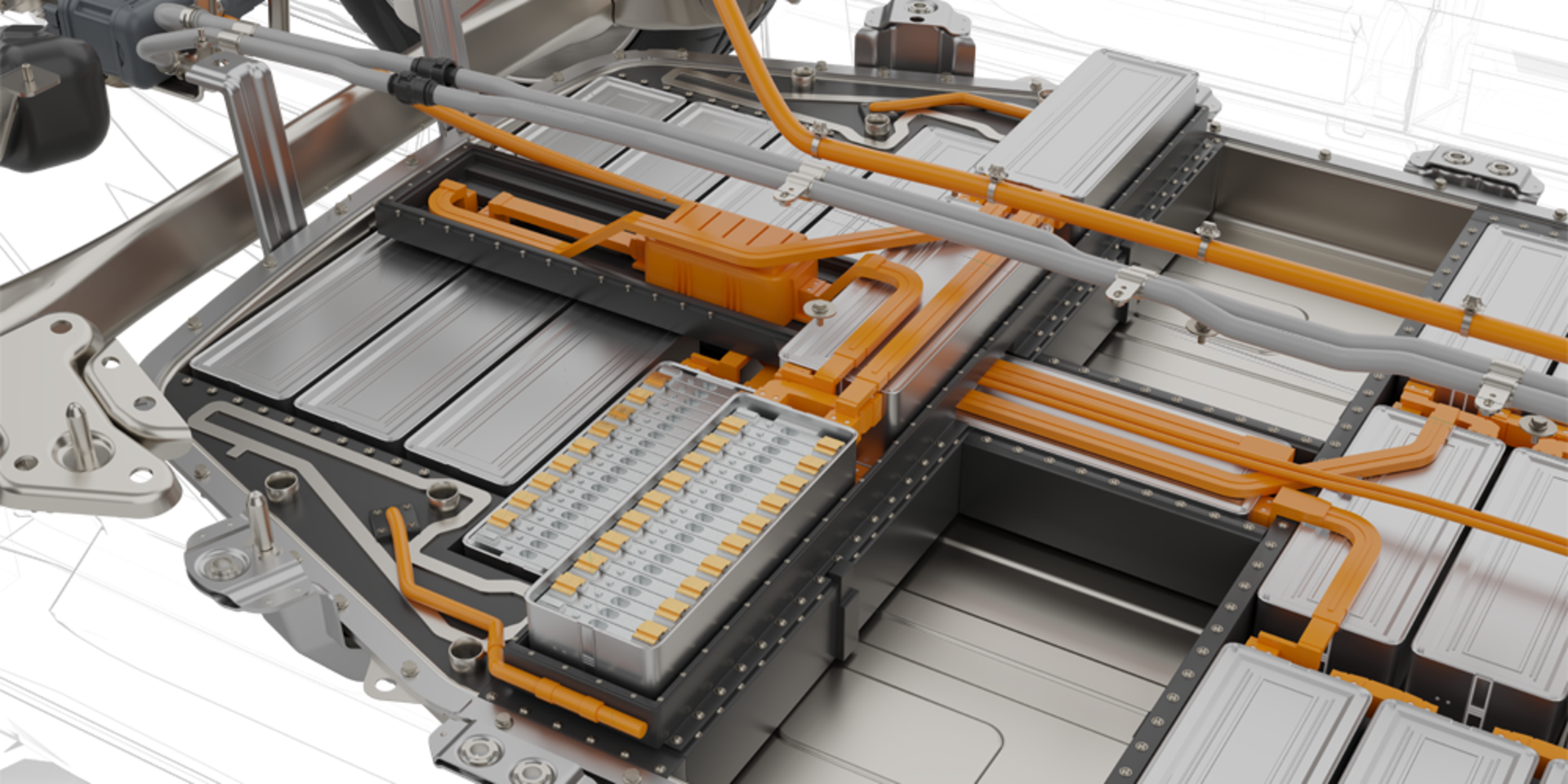

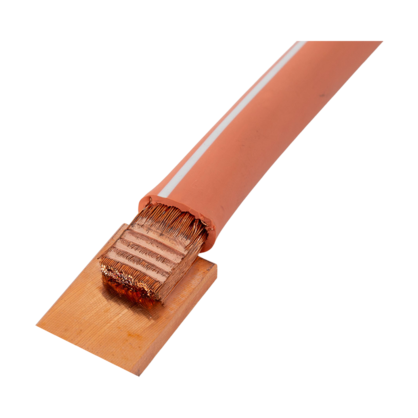

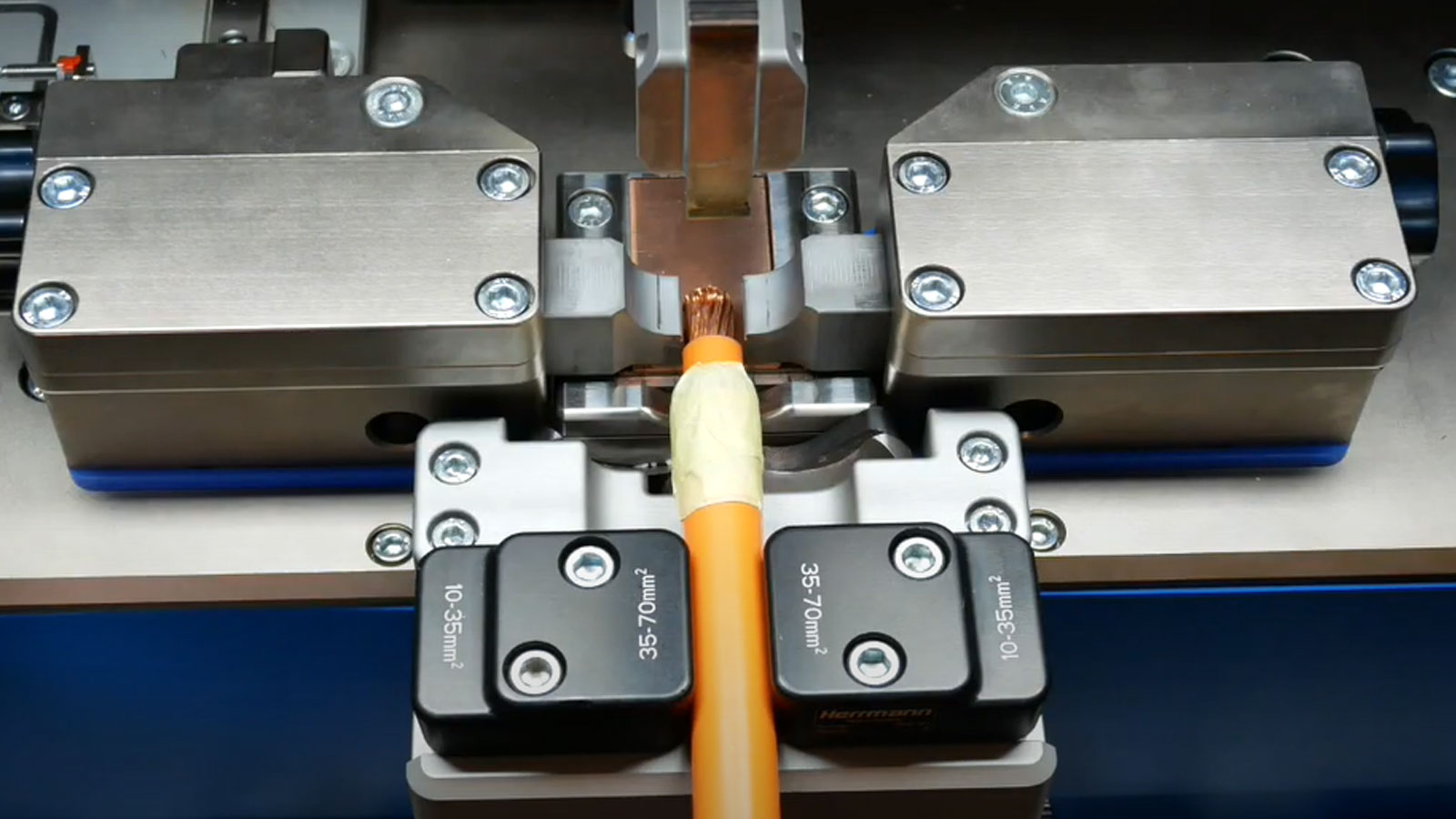

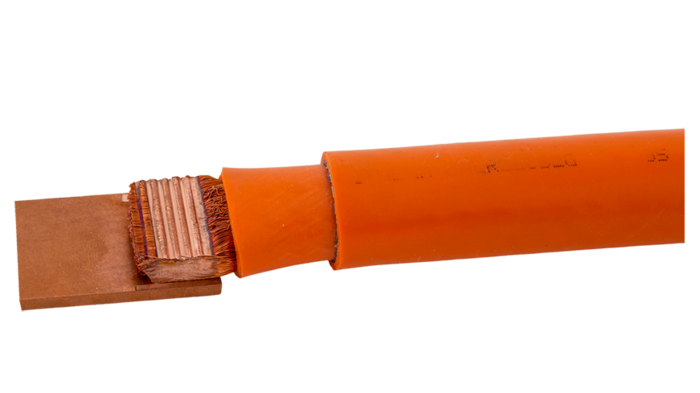

High-voltage cables for automotive industry

A special form of cable to terminal applications is the welding of high-voltage cables. They are essential for the success of electromobility, but due to their large diameter, a reliable connection requires a lot of power. With forces of up to 10,000 N, ultrasonic welding machines are perfectly suited for permanently and firmly joining high-voltage cables.

Low cycle times are possible even for cables with a cross section of up to 150 mm², ensuring economical production.

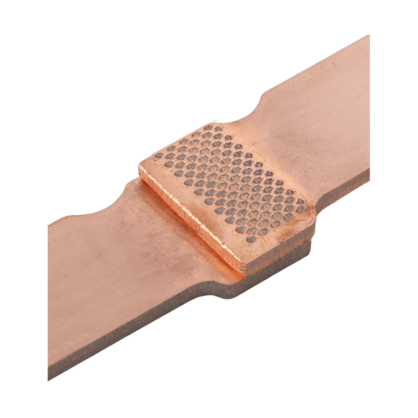

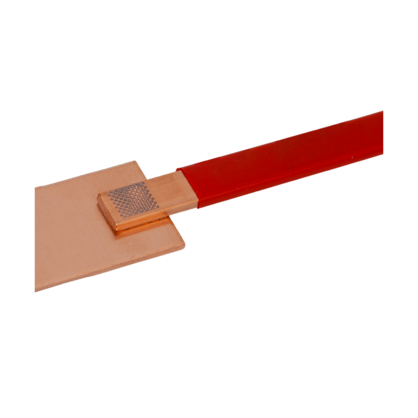

Busbar / terminal to terminal

When welding terminals or busbars, sheets with a thickness of up to 5 mm are welded together. These are used when high currents have to be transmitted, as for example in battery management systems or high-current contacts. Therefore, the force and power requirements are also considerably higher.

With ultrasonics, the connections can be welded in fast cycle times without having to accept losses in conductivity.

FAQ – The Most Important Questions and Answers about Welding Metals with Ultrasonics

Ultrasonics can be used to safely connect the same and different non-ferrous metals within a very short time. It is mainly used for the connection of conductive non-ferrous and precious metals. These include aluminum, silver, copper and nickel in particular, with aluminum-copper connections accounting for 90% of applications.

Weldable non-ferrous metals are all pure metals except iron as well as alloys (connections of different metals) that have less than 50 percent iron content. Pure ferrous metals cannot be joined with ultrasonics.

Due to the optimal conductivity of the connections and the short welding times, ultrasonic welding has established itself as a joining technology for numerous applications consisting of non-ferrous metals. These typically include:

- Wire-terminal

- High-voltage cable

- Busbar / terminal terminal

- Lithium-ion battery (LIB)

- Pouch cells and flexible housings

- Battery management systems

Learn more about ultrasonic welding for your wire-terminal application.

Ultrasonic welding is a joining process without additional joining agents. Mechanical vibrations are created by an ultrasonic generator and converter. The welding tool, the so-called sonotrode, transfers these mechanical vibrations to the components.

One joining part vibrates in the longitudinal direction, while the other remains secured in the fixture. Friction breaks up the oxide layer and the parts are welded together at the same time under pressure.

The decisive factor in welding is not the heat generated, which is well below the melting point, but the relative movement of the two joining partners.

Learn more about the principle of ultrasonic welding for wire-terminal applications.

Ultrasonic welding of metals has several advantages over conventional welding methods such as soldering, crimping or laser welding:

- Speed: The welding process with ultrasonics only takes fractions of a second. Without the need for additional cooling times, production cycles can be significantly accelerated.

- Reliability: The specification and monitoring of numerous welding parameters ensures precise and reproducible welding results. This is a decisive advantage, especially when welding sensitive and small metal parts, such as in batteries.

- Cost efficiency: Ultrasonic welding does not require any additional joining materials such as solder.

- Sustainability: Ultrasonics welding requires very little energy as it does not use heat to connect metals and does not require the use of chemical tools.

- Safety: Ultrasonic welding produces no sparks or smoke, which makes it safe to work in manufacturing.

- Gentle: Materials are not damaged or deformed outside the defined weld area.

Learn more about the benefits of ultrasonic welding for your wire-terminal application.

When welding with ultrasonics, the ideal parameters are determined individually for each application via test series in the ultrasonic laboratory. These can be reproduced exactly thanks to the precise process control.

Up to 150 different welding data can be recorded, saved and exported for each individual welding process. This monitoring is fully automated and ensures seamless digital quality control.

This ensures a safe, reliable process and minimizes scrap rates – and costs – over the long term.

Learn more about the benefits of ultrasonic welding for your wire-terminal application.

Partner with Us

Contact our team to discover how our premium solutions can elevate the quality and effectiveness of your large-scale manufacturing.