Successful ultrasonic solutions

Sealing through contamination

- With ultrasonic sealing, packages are sealed 100 % tightly even if there are residues of the contents in the seam area.

- In the sealing process, the vibrations of the ultrasonics displace these residues reliably from the sealing zone – regardless of whether the contents are solid, moist or liquid.

This significantly reduces rejects and at the same time extends the shelf life of the products.

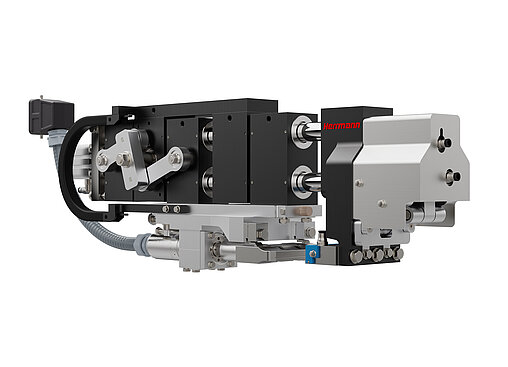

Food Cutting with Ultrasonics

Up to 5 % more OEE with 100 % clean cuts: Discover our solution for industrial food cutting of applications like cake, chocolate or enery bars. Thanks to the long service life of our sonotrodes, we can help you maximize your output and efficiency in your processes.

Explore new solutions today

Download Expert Resources

Learn more about the benefits of our technology for your food applications. Our downloads contain the knowledge from over 60 years of ultrasonics, providing valuable insights into advanced assembly techniques. By sharing our technical knowledge with you, we ensure a close partnership on equal terms so that we can realize projects as quickly and successfully as possible.

Download our exclusive resources to unlock decades of innovation and stay ahead in the rapidly evolving food industry.

Partner with Us

Contact our PACKAGING Team to discover how our premium solutions can elevate the quality and effectiveness of your large-scale manufacturing. We look forward to hearing from you!