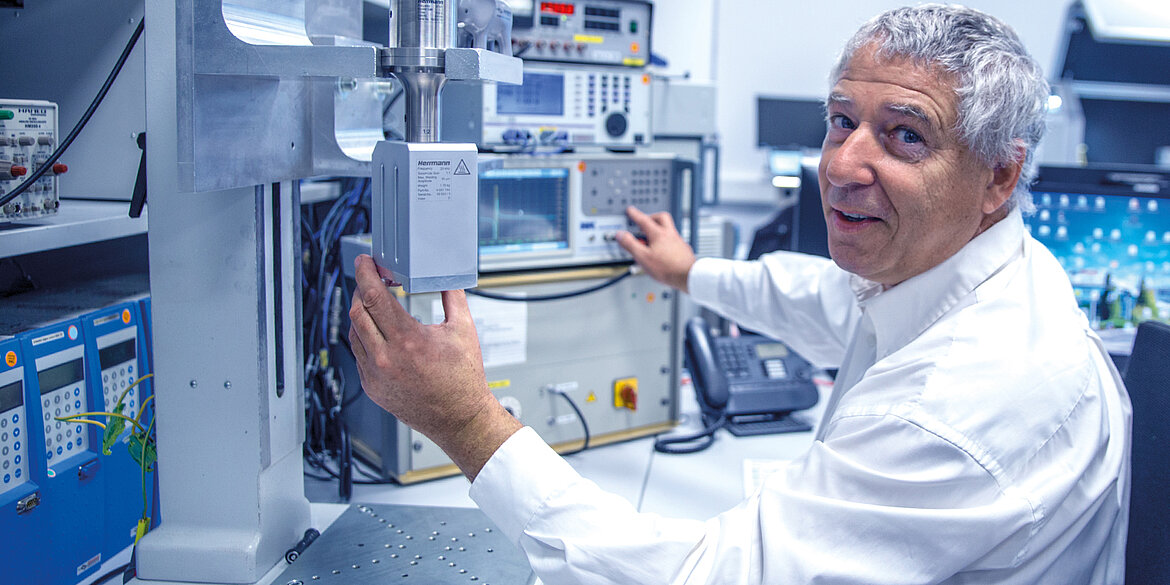

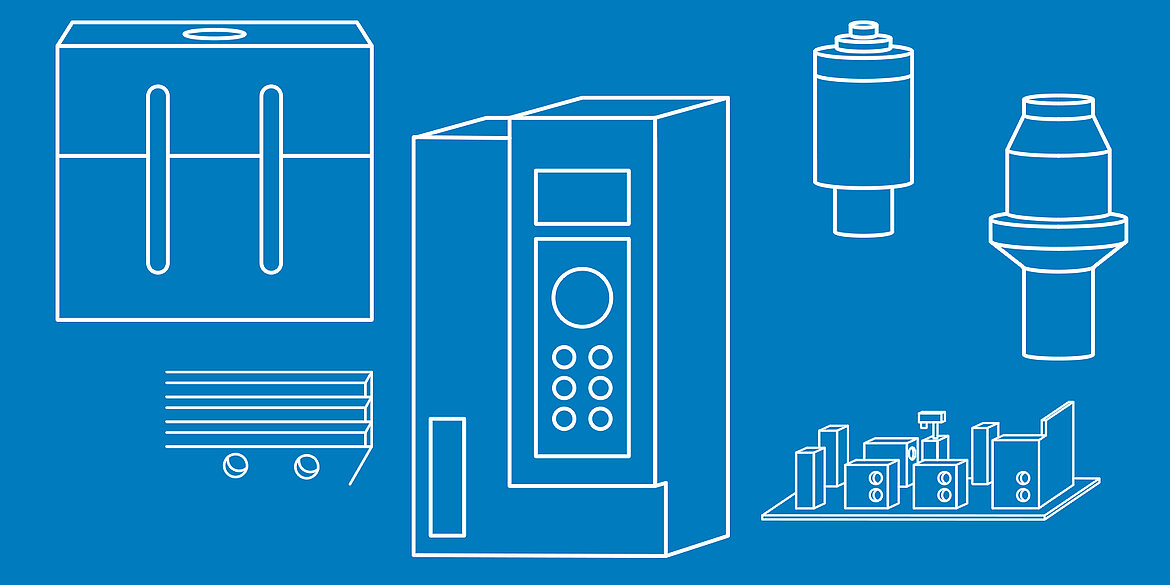

Herrmann’s ultrasonic technologies fulfill all crucial criteria of process optimization and allow for full process data collection. We provide solutions for more than 1500 customized projects every year. As the leading provider of ultrasonic equipment and solutions for automotive assemblies, Herrmann Ultrasonics is the industry’s top partner. Our expertise in a wide variety of automotive assembly solutions means we provide complete ultrasonic welding systems as well as a full range of components ready for custom integration to meet the needs of the production floor. When manufacturers turn to us for complete know-how concerning ultrasonic welding in the automotive industry, they benefit from our experience and advanced technologies.

We can help our clients integrate automated ultrasonic welding into automotive assembly lines to achieve greater efficiency and ultimately a better finished product. Our high-quality machinery and components are used to provide strong, repeatable bonding of various materials including nonferrous metals and plastic.

Application groups

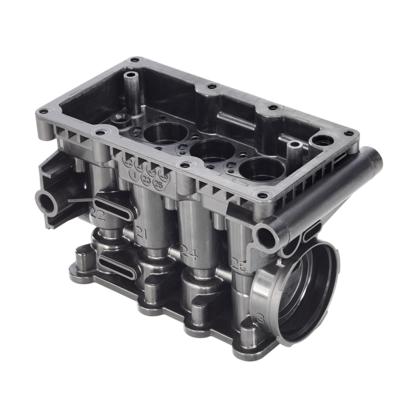

Drive components

Tightness, pressure and burst resistance, and unrestricted functionality: ultrasonic welding fulfills these requirements for vehicle components in the engine compartment. In filter applications, the filter material must be reliably embedded and the weld must be resistant to both heat and cold.

The requirements for lithium-ion batteries, battery management systems and wire harnesses are high tensile strength, durable process stability, minimal rejects and low heat exposure zone.

Strong connections for wire + terminals

From smaller terminals to large-diameter high-voltage cables: the demand for reliable connections is increasing rapidly, not only thanks to electric vehicles. Ultrasonic welding ensures strong connections without any loss of conductivity, making it the ideal technology to meet this demand.

Take advantage of ultrasonics and benefit from the efficient technology that reliably joins non-ferrous metals in the shortest time possible and with little energy!

Functional components

Complete functionality, without restriction, of integrated functional elements is ensured in ultrasonic welding of such components. What is more, 100% control and documentation of weld process parameters is guaranteed. Using ultrasonics it is also possible to punch and weld membranes within a single machine cycle. These membranes typically serve as pressure balancing elements (DAE) in sealed assemblies that must withstand temperature variations while maintaining a liquid-tight seal.

Cutting tire rubber

Ultrasonics is a well-established cutting technology used to cut raw tire rubber cleanly with precision and a high level of consistency.

Thanks to its sturdy components from Herrmann, the ultrasonic stack will improve your ROI. We guarantee that the service life of your cutting tool will be significantly extended. It will also allow you to avoid down time and improve your output.

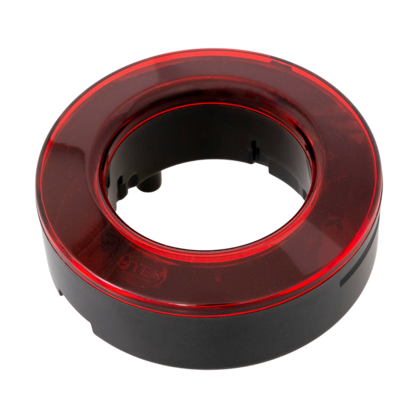

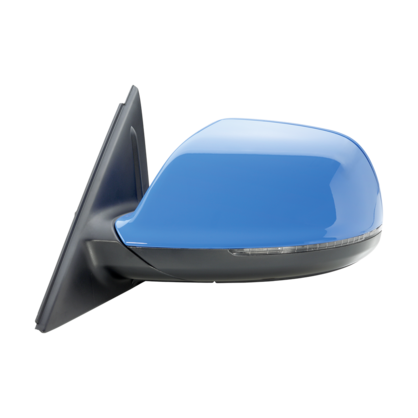

Exterior and lights

Strength, tightness, dimensional accuracy flawless cosmetic appearance are typical requirements of these assemblies. Ultrasonic welding is a low-stress process for components and its versatility makes complex component geometries possible.

Interior

Ultrasonics is not only suitable for automotive plastic welding, but also for joining plastics and other materials, such as metal, or wood Through custom sonotrode designs and clever positioning, it is also possible to realize particularly demanding joining tasks, such as welding of large instrument clusters. Brilliant surface finish and precise gap control is achieved.

To learn more about everything we can do for you and your operations, get in touch with us today.

Ultrasonic Staking

Shorten cycle times in the automotive industry! With a brand new and superior Sonotrode Design, the staking process will be 25% faster and lowers energy costs, all at once.

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/1/9/csm_PR_ULTRASAFE_open_front_Web_fd9116bbf2.jpg)