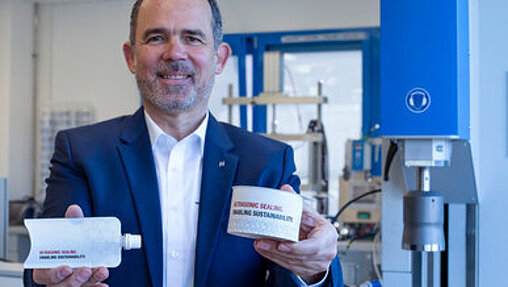

For packaging with thermoplastic layers, such as capsules, pouches, drink cartons, cups, and trays, ultrasonic sealing provides many benefits: above all, high cycle rates and tight seals despite potential product residues in the seal area. Our food packaging sealer technology is used for sealing plastic films as well as laminating nonwoven materials found in certain types of food packaging.

Ultrasonic sealing of food product packaging fulfills all regulations and criteria of process optimization crucial for companies in this sector. Herrmann Ultrasonics is ready to provide you with full expertise to implement and integrate this equipment into your operations.

Successful ultrasonic solutions

Capsules, tea bags

Sealing of film lids, welding of seal rings, and embedding of filters are some of the most common applications. The weld tools hold the film in place by means of vacuum. Shelf life and product protection are ensured due to the tools being cold. This makes our technology ideal for products like single-serve coffee pods, which requires contents to remain sealed for freshness.

Spouts, valves, zippers

With ultrasonics, film shrinkage is prevented and the barrier properties are not jeopardized, since ultrasonics only excite the molecules in the actual sealing layer. Moreover, ultrasonics allow for safe integration of zippers for re-sealable pouches and welding of the zipper ends (zipper-crushing).

Film packaging

With ultrasonics, you can safely push product residues out of the seal area, which ensures a stable, tight seal. This significantly reduces leakage and extends the shelf life of the product. Ultrasonics provide this advantage for film pouches, plastic bags, and other food packaging materials. Utilized at longitudinal and transverse joints, in intermittent and continuous applications.

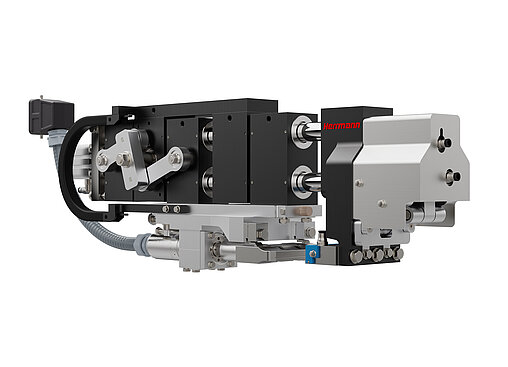

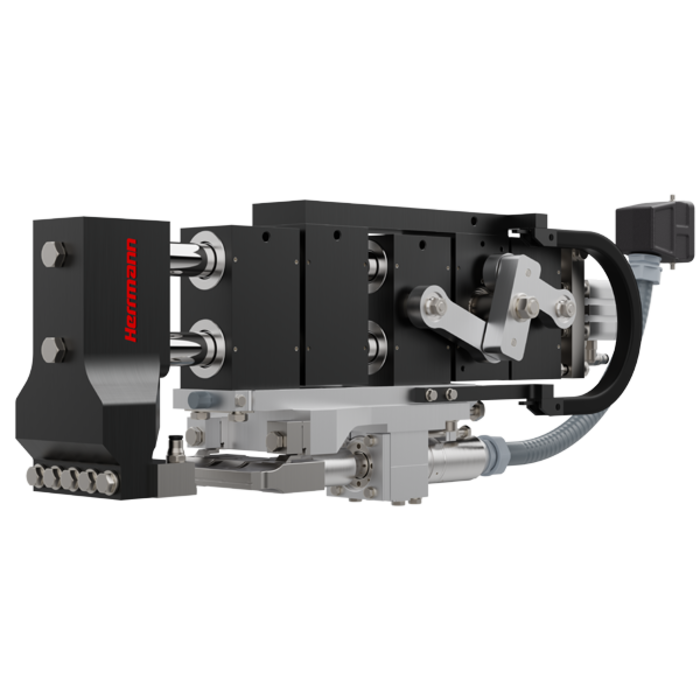

Drink packaging

Ultrasonic welding is well suited for coated carton packaging material. Despite interference with filled products, tight seals are ensured with or without a barrier. Integration of spouts in liquid products is easily possible. Delivers high output due to short sealing times, and repeatable parameters ensure consistent, high-quality sealing.

Cutting

Clean cuts without deforming the product. The sonotrode precisely separates the food without leaving any remains on the welding tool. This also prevents any smearing, resulting in an optically perfect result. As a result, you not only increase the quality of your products, but also reduce product waste and costs.

Blister packs, trays, bowls

For PET applications, ultrasonic automatic cup sealing quickly reaches melting points, resulting in increased production output. Our plastic cup sealer technology has the potential to process more units per hour than other cup sealing systems. Used in the sealing and separating of blister packs, tear-out sections, and tamper-evident seals.

Sealing through contamination

- With ultrasonic sealing, packages are sealed 100% tightly even if there are residues of the contents in the seam area.

- In the sealing process, the ultrasonic vibrations displace these residues reliably from the sealing zone – regardless of whether the contents are solid, moist, or liquid.

- This significantly reduces rejects and at the same time, extends the shelf life of the products.