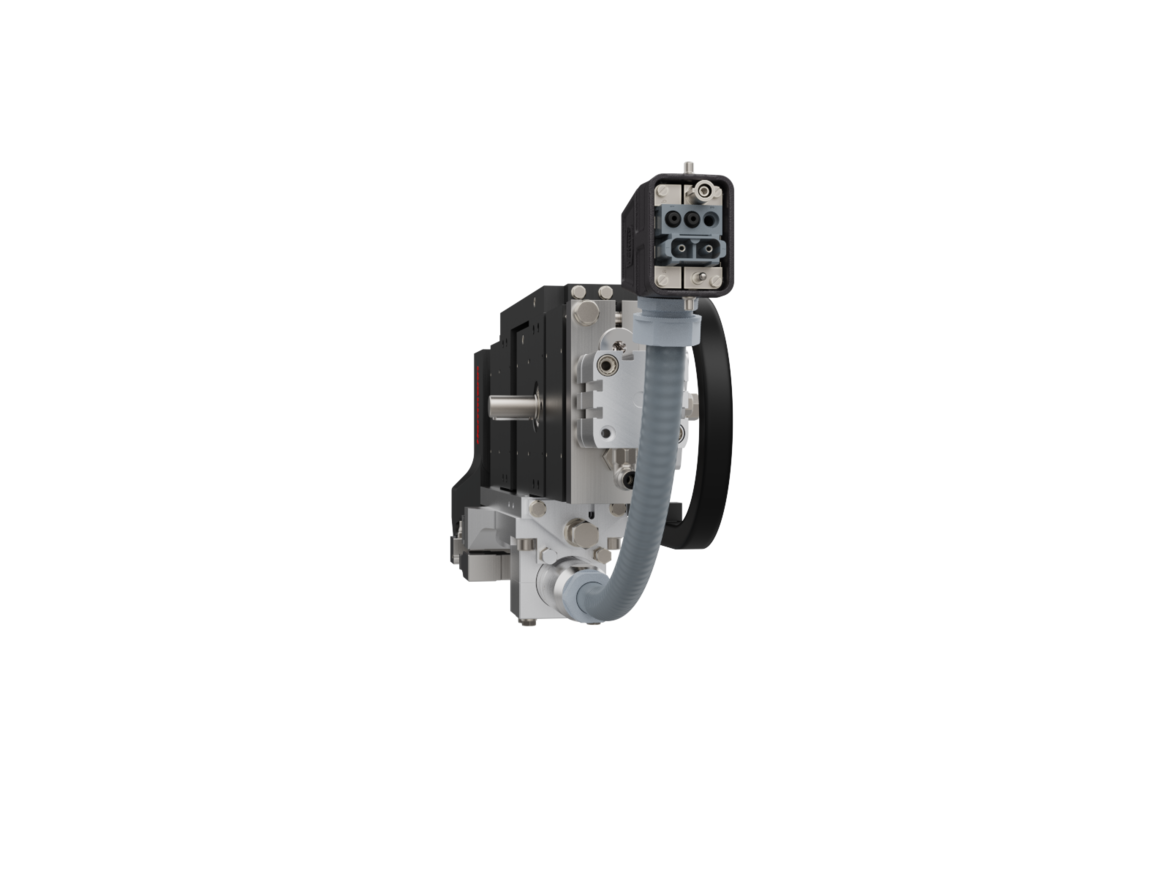

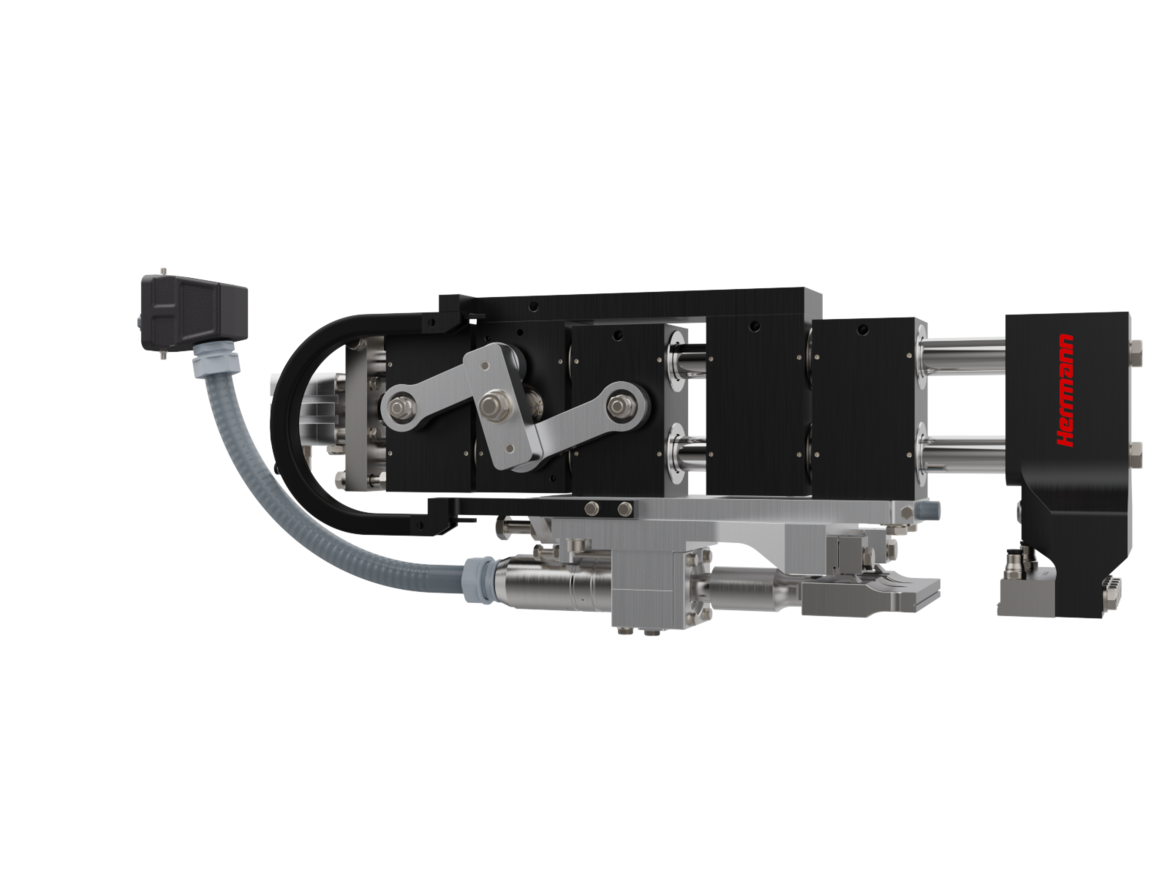

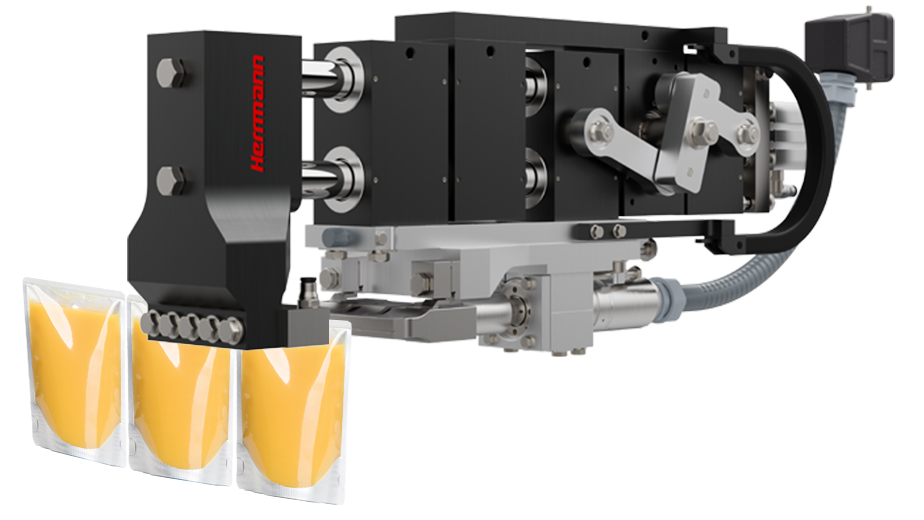

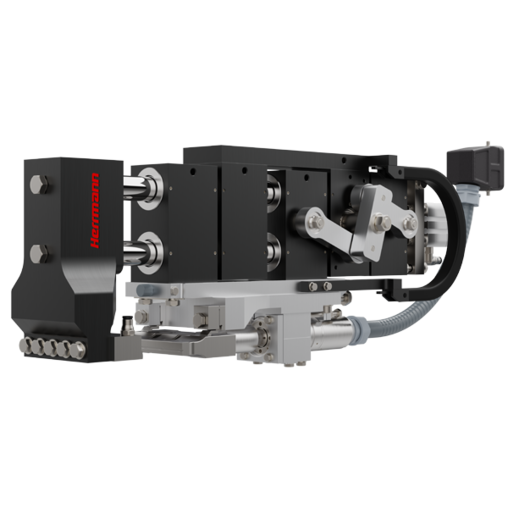

TSM Top seal modules

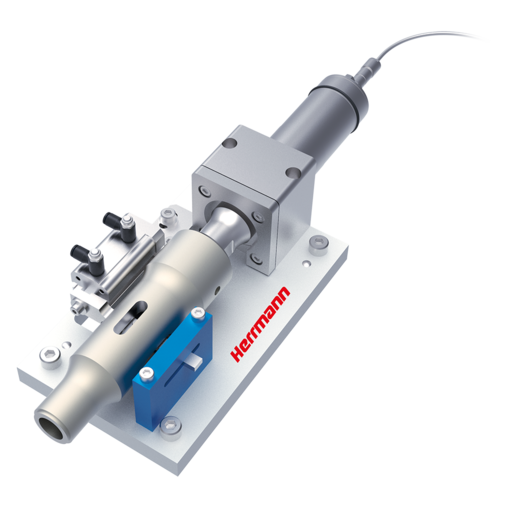

The top seal module from Herrmann brings together the experiences from more than 1,000 top-seal sealing stations on the market. With its modular design, it is configurable for a variety of packaging machine types.

- 30 and 35 kHz operating frequency

- up to 207 mm sealing length

- up to 1200 N sealing force

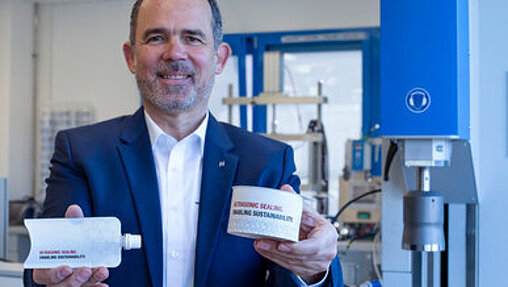

The PACKLINE modules from Herrmann achieve strong and hermetic sealing. Burns caused to the packaging material during machine downtimes are safely prevented. The top seal module is optimally suited for integration in new machinery or as retrofit for existing machine designs. If the tools are designed with protection class IP65/67, the top seal module is also suitable for use in wet environments with advanced cleaning capability requirements.

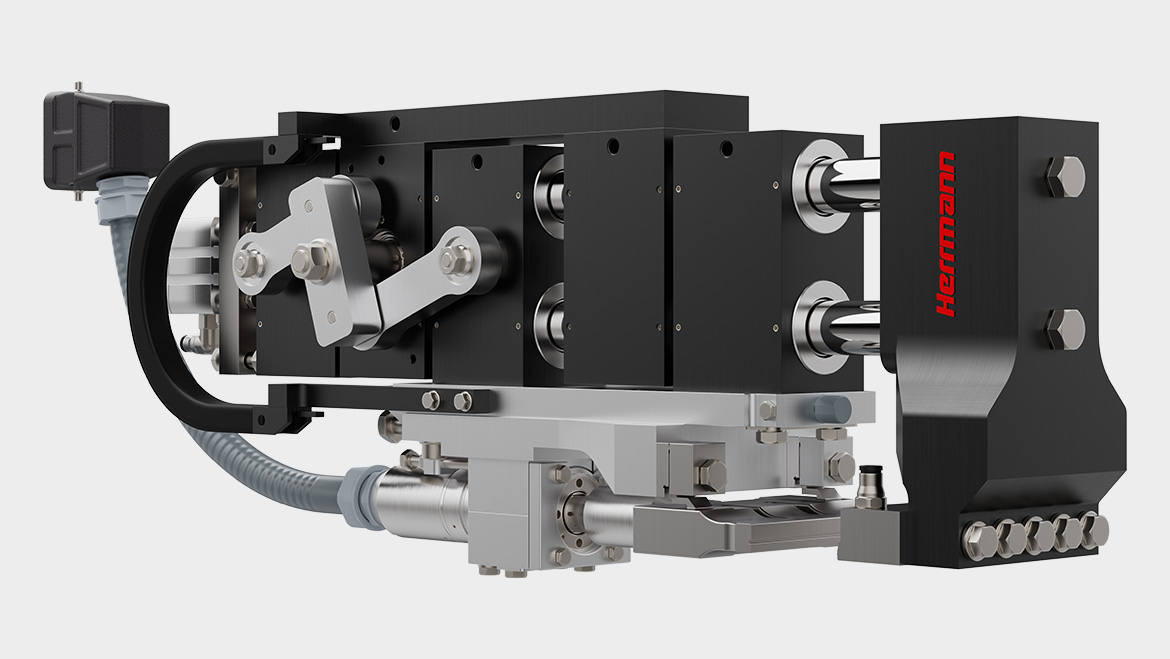

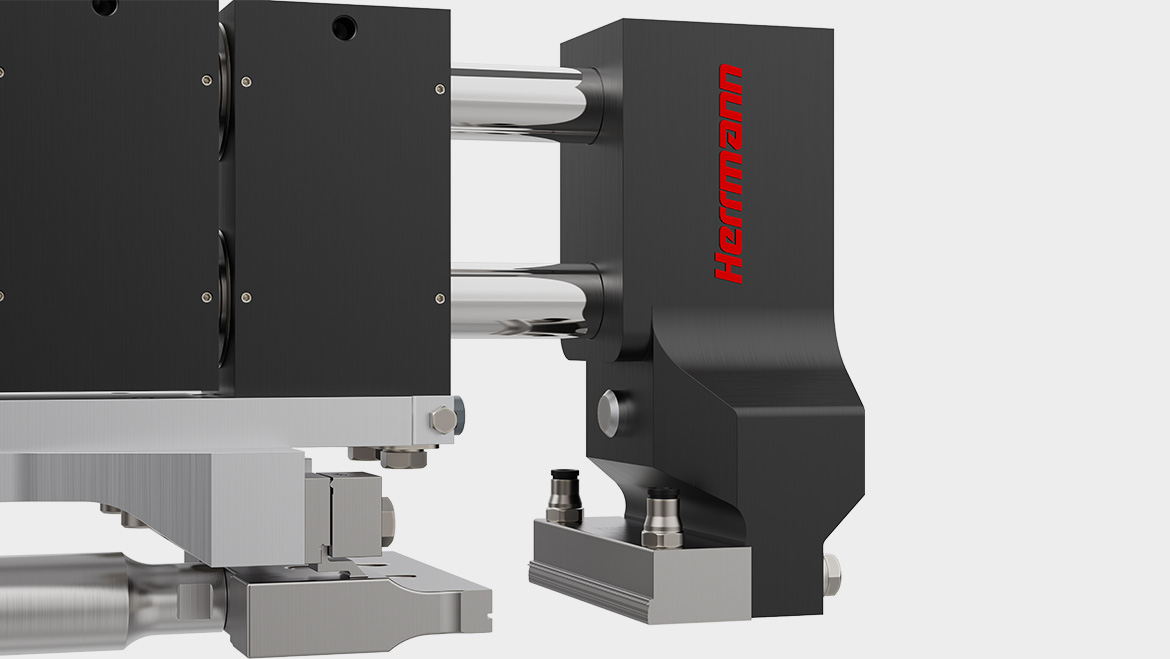

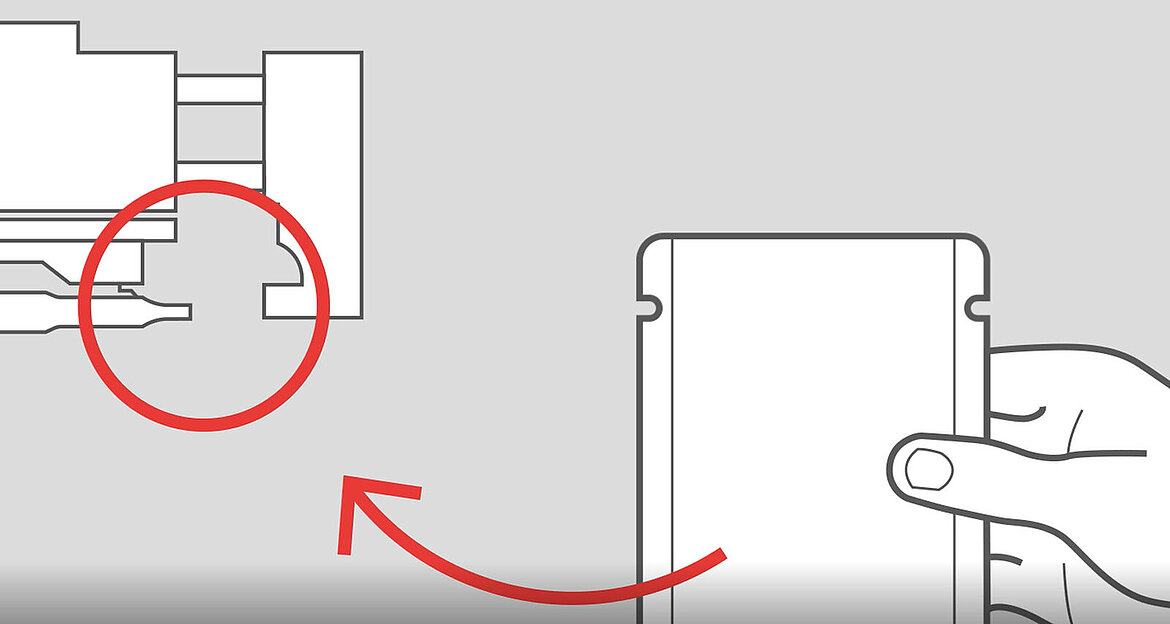

The pneumatic generation of force is integrated in the top seal module, which results in considerable freedom as regards the drive concept. Pneumatic and electric drives can be adapted on the drive shaft. A mechanical connection with the main drive shaft of the packaging machine can also be realized. To fulfill various assembly conditions, the drive may be installed on either the left or the right side of the module – this is particularly beneficial in the case of multi-line systems.

The integrated pneumatic cylinder means that the sealing force is immediately available with the contact of the sealing tools. This PreLoaded concept allows for the process-safe sealing of pouches, also with high machine speeds.

- Flexible in the drive selection

- Configurable installation

- Safe sealing at high cycle rates thanks to PreLoaded function

| Top seal module TSM | 30 kHz | 35 kHz |

|---|---|---|

| Generator power [W] | 1800 | 1200 |

| Max. weld force at 6 bar [N] | 750/1200 | 750/1200 |

| Max. sealing length [mm] | 207 | 135 |

| Max. opening width [mm] | 50/100 | 50/100 |

| Drive configuration | Left hand/right hand | Left hand/right hand |

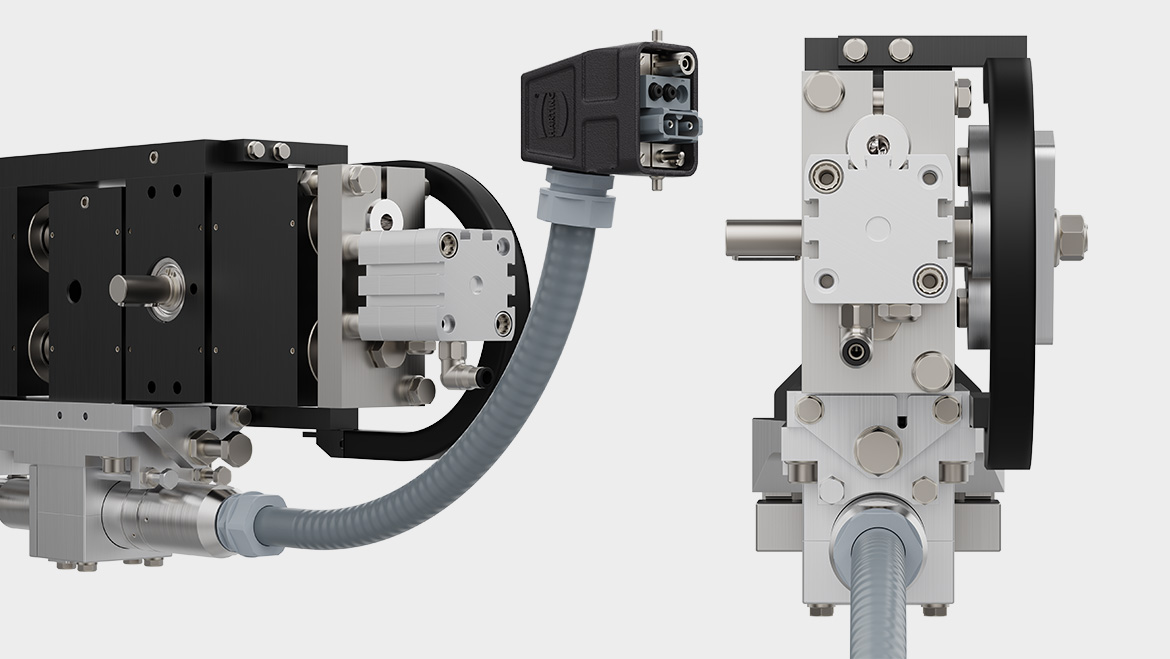

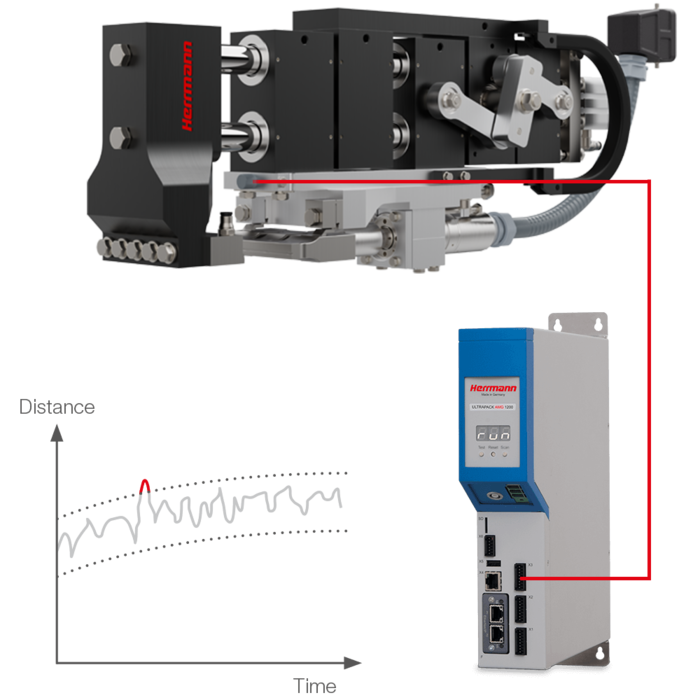

HDM ProcessControl

The “High Precision Distance Measurement” function is a quality control which recognizes faulty pouch conditions in the sealing stations and enables suspect pouches to be rejected. The HDM sensor which is integrated in the TSM determines the distance of the sealing tools. The signal is evaluated directly on the ultrasonic generator that allows for exceptionally high evaluation speeds, which are particularly advantageous on high-speed top sealer sealing machines. The intelligent generator management can compensate for thermal influences, which means a constant quality control is guaranteed throughout the entire machine running time.

Recognizable faulty conditions

- Double pouches

- Folded pouches

- Solid product in seal area

- Missing pouches

Customer benefits

- Reduction of faulty pouches in the actual yield (downstream)

- Reduced effort in the quality control

- Prevention of metal contact of the tools for a long service life

Advantages of ultrasonic sealing technology

- Tight and strong sealing, even with seal contamination

- Short start-up time, as no heating of the sealing tools required

- Cold sealing tools protect the product during the filling

- Integrated quality control

- Suitable for wet cleaning due to protection class IP65/67

Application examples

- Wet pet food

- Ready meals

- Pickled cabbage / red cabbage

- Drinks

- Herbs and spices