Customer Story Beckmann Converting

Pushing the boundaries of textile manufacturing, Beckmann Converting Inc., a leading toll converter specializing in unique textile applications, recently partnered with us to upgrade a key laminating machine. This strategic collaboration was driven by the evolving needs of the industry, particularly the emergence of novel, more sustainable materials which presented unique production challenges.

Beckmann Converting chose us due to our over 60 years of expertise in ultrasonic welding, particularly in textiles and nonwovens, and our proven ability to deliver highly consistent, repeatable, and efficient bonding solutions.

The challenges

- Beckmann Converting faced difficulties handling novel, sustainable materials, experiencing issues like bagginess, wrinkles, and inconsistent bonding during lamination especially across wide-width applications.

- There was a pressing need to increase production speed and efficiency to meet growing customer demand for faster turnaround times and higher order volumes.

- They sought to maintain consistent and reliable bond strength across diverse and complex multi-layer laminate structures, despite evolving material properties.

Our solution

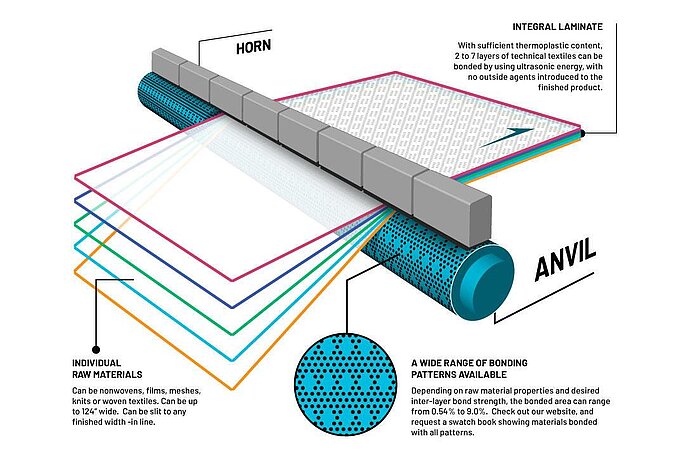

- The new solution centered around a state-of-the-art ultrasonic bonding system, specifically designed for Beckmann Converting's needs.

- Utilizing high-powered ultrasonic generators and advanced motion control ensured precise and consistent bond strength across the entire material width.

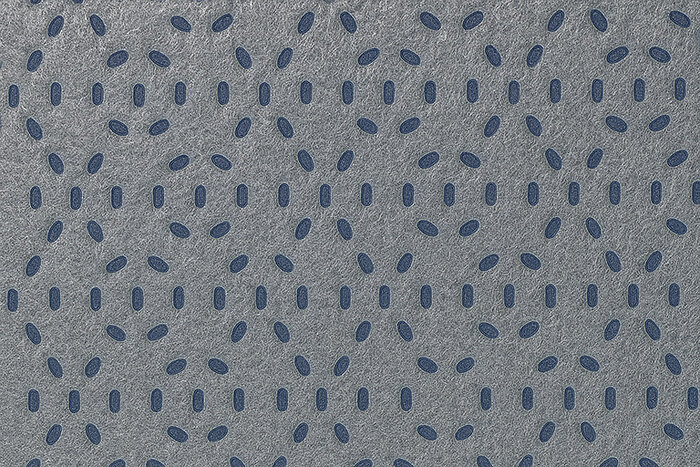

- This enabled the exploration of new bonding patterns, such as the "CC" roll, offering superior inter-ply adhesion for high-strength applications.

The new ultrasonic bonding system ensured precise and consistent bonding across wide applications, minimized material distortion, and maximized uptime, ultimately addressing production bottlenecks and enhancing product quality.

Customer benefits

Our solution allowed them to expand their product portfolio with innovative bonding patterns, leading to improved laminate quality with consistent and reliable bond strength. Production capacity saw a substantial increase due to faster setup and cycle times, while the elimination of adhesives led to reduced maintenance costs. These enhancements collectively boosted Beckmann Converting's competitive edge in the textile market.

Consulting as a Success Factor

Herrmann Ultrasonics excels in providing tailored solutions for complex manufacturing challenges, recognizing that each application is unique. Through in-depth analysis and the expertise of our engineers, we custom-designed an ultrasonic bonding system that precisely met the stringent demands, including consistent bonding across 126-inch widths. This personalized engagement, from initial assessment to system implementation, is what truly enables our partners to achieve revolutionary improvements in efficiency, quality, and overall production capabilities.

Find out more in the complete customer story

Partner with Us

Contact our team to discover how our premium solutions can elevate the quality and effectiveness of your large-scale manufacturing. We look forward to hearing from you!

![[Translate to USA - Englisch:] [Translate to USA - Englisch:]](/fileadmin/_processed_/6/f/csm_TEi_7f015ae83d.jpg)